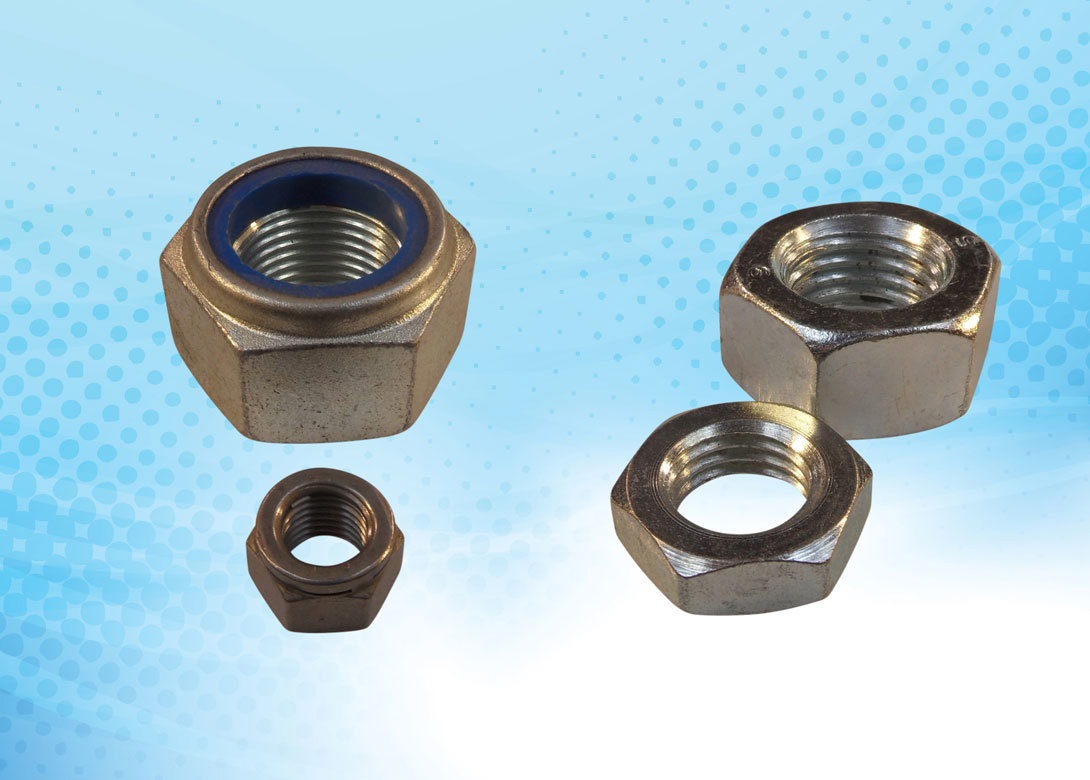

Challenge Europe is pleased to offer ex-stock threadlocking solutions for general industrial assembly purposes. One of the most common and simplest solution to problems of vibration loosening of threaded fasteners is by use of a conventional locking nut or half nut.

Use of a full nut provides an easy fitment which pulls from the same stock as the main fastener. A locking half nut above the full nut leaves “head room” – indeed, where two half nuts are used, this can make a quite significant difference in cramped situations.

Full nuts are available in all metric sizes to fit screws and bolts. Commonly they are available as cold forged parts but larger sizes are often bar turned from hexagonal bar. Half nuts are available in steel, stainless steel or brass.

Ex-stock self-locking nuts are frequently a preferred solution since they reduce the number of operations and order lines. Also known as stiff nuts and sometimes prevailing torque nuts, these are available in a range of styles but they all operate in a similar way having an interference fit mechanism that provide anti-loosening characteristics. Standard reference types include nylon insert nuts, Philidas® nuts, Binx® nuts, Aerotight® nuts and Stover nuts.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.