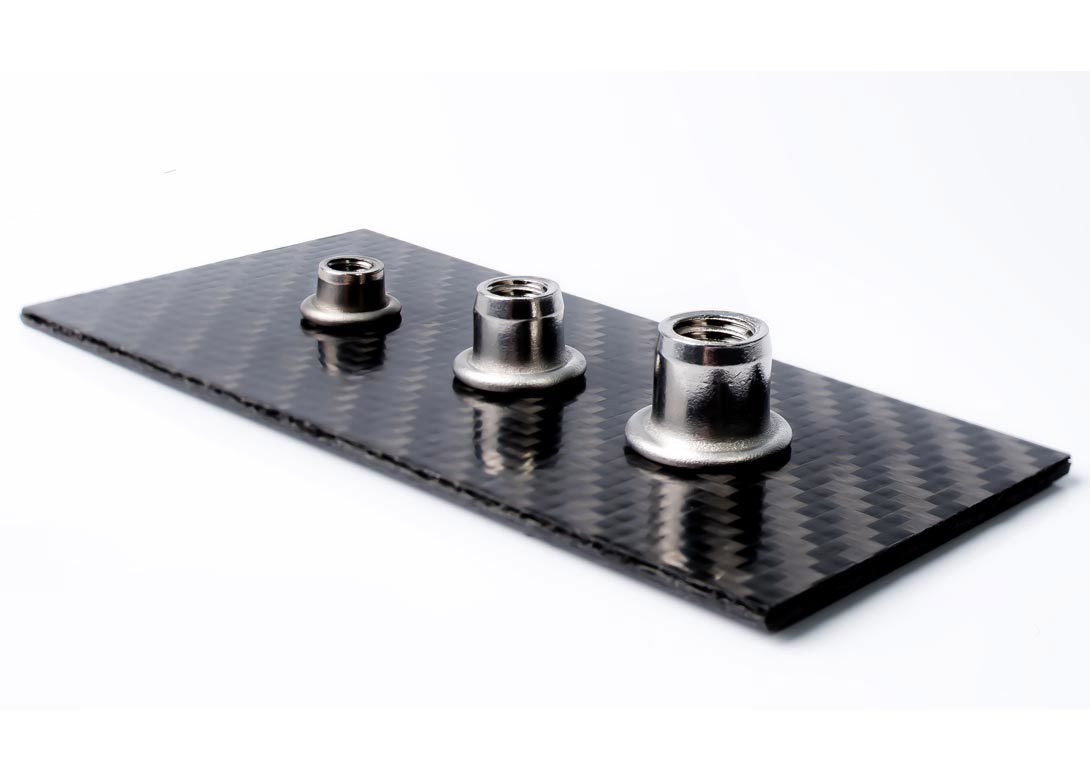

GESIPA explains that its CFRP blind rivet nut now makes it possible to easily incorporate functional elements into fibre-plastic composites without material damage. This is achieved through a special geometry of the blind rivet nut. The deforming process is highly controlled so that damage to the component by setting forces is prevented. The closing head assumes a large diameter shape ensuring safe spread of the clamping force.

Due to its special form, the blind rivet nut can be used in a large clamping range, and can be used for various applications within a production process. This saves handling costs and keeps the storage costs low. The material used fits well with the CFRP and keeps away any possible corrosion. GESIPA points out that even after 1,008 hours in the standard salt spray test, the results showed zero or very little red rust could be detected.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.