BASF and Toyota Motor North America Research and Development achieved lightweighting success with the new 2021 Toyota Sienna. The vehicle, scheduled to launch later this year, just won the prestigious Altair Enlighten Award for achievements in vehicle weight savings for reduced mass of the third row seat.

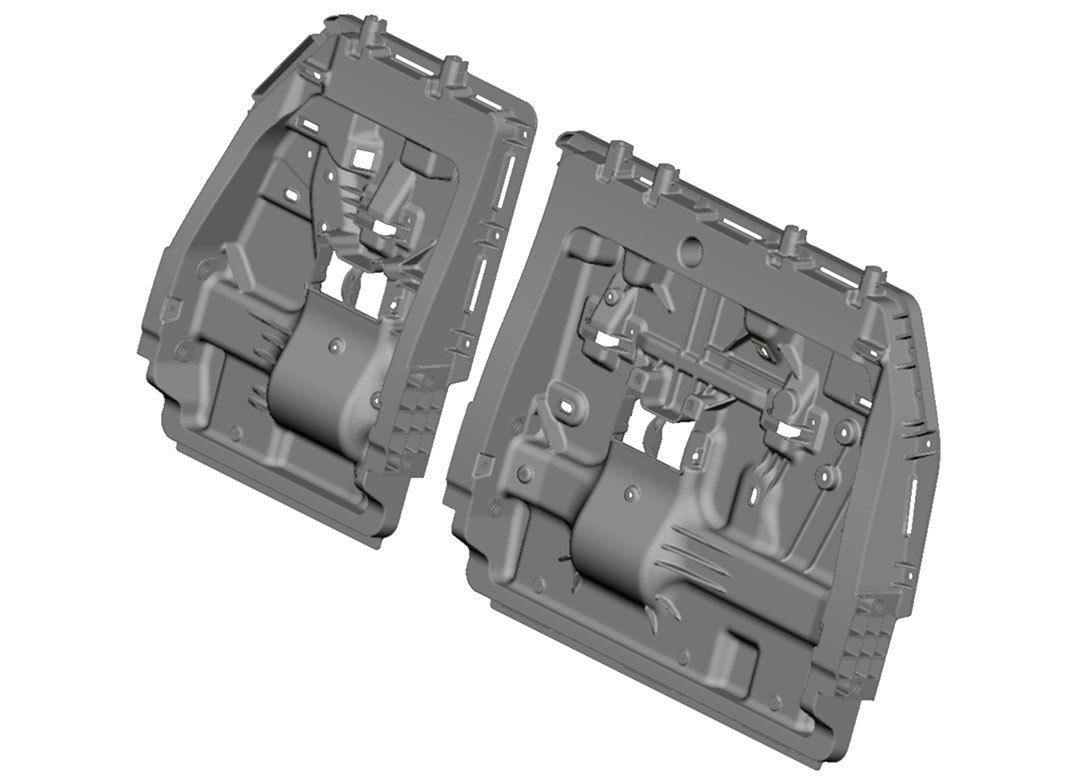

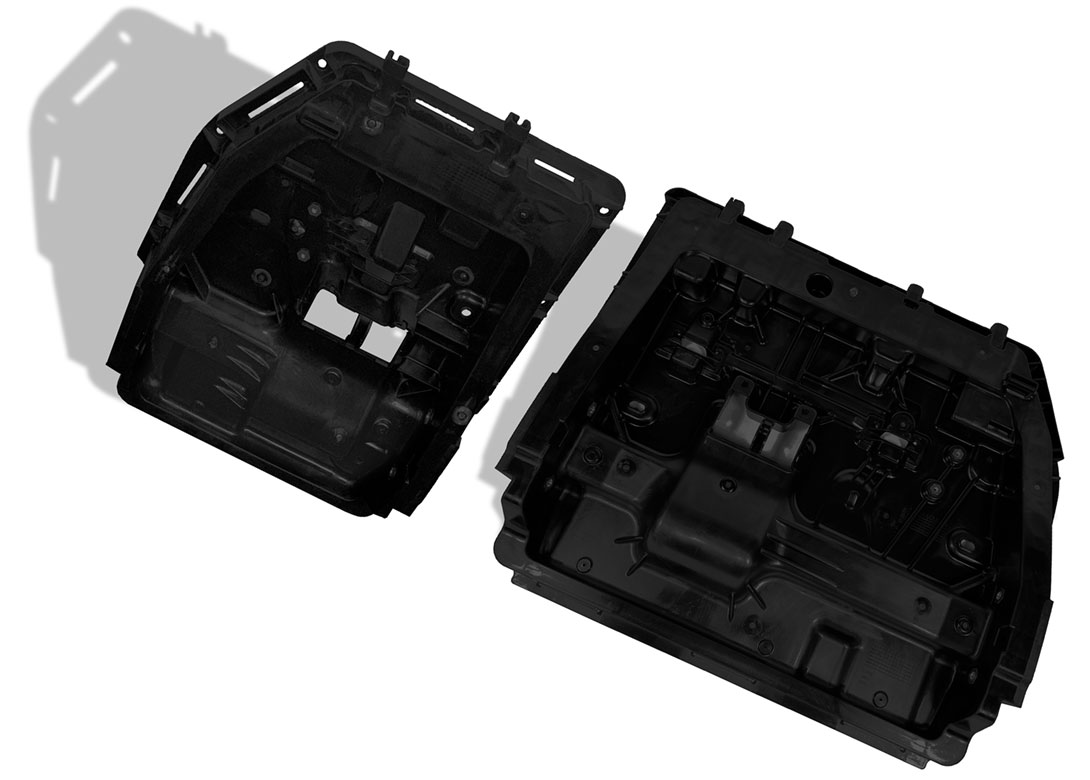

In the previous model, the third row seat was comprised of 15 different steel components, making it very heavy. Toyota wanted the 2021 Sienna’s third seat to be lighter and cost competitive while exceeding all performance criteria. Toyota turned to BASF to help them achieve the lightweighting goal. “Lightweighting doesn’t always have to be more expensive,” said Todd Muck, from the Toyota technical strategic planning office at the Toyota R&D Center in Saline, Michigan. “We were able to meet our cost objective and saved 15% compared to the prior generation. The seat is 30% lighter compared to the previous model. We had some great partnerships that helped us achieve these targets, one of which was BASF.”

Traditionally, resin components for seating have had metal reinforcement, which can add more cost to the process. Toyota also wanted an injection molding part that was a shoot-and-ship part – meaning it was made in one piece, without complex and costly post-processing. That’s where BASF’s expertise in materials and design came in. BASF used its unique 35% glass-reinforced and impact-modified polyamide PA6 grade Ultramid® B3ZG7 CR, and its proprietary computer aided engineering (CAE) tool ULTRASIM® which allowed for an accurate CAE simulations during the multiple phases of development efforts.

“The third seat design is what I would classify as an enabling technology,” said Matt Parkinson, manager applications development engineering and composite technologies, BASF performance materials. “It is the first of its kind in the way it is designed without inserts as a fully injected seat back. One of the challenges was to ensure a high elongation and impact qualities for the crash requirements. At the same time, we focused on strength and stiffness because the seat also serves as a load floor.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.