Arnold has developed a proprietary fastener for friction element welding, with the aim to offer customers services for every aspect of car body construction - even joining lightweight sheet metal to high-strength steels.

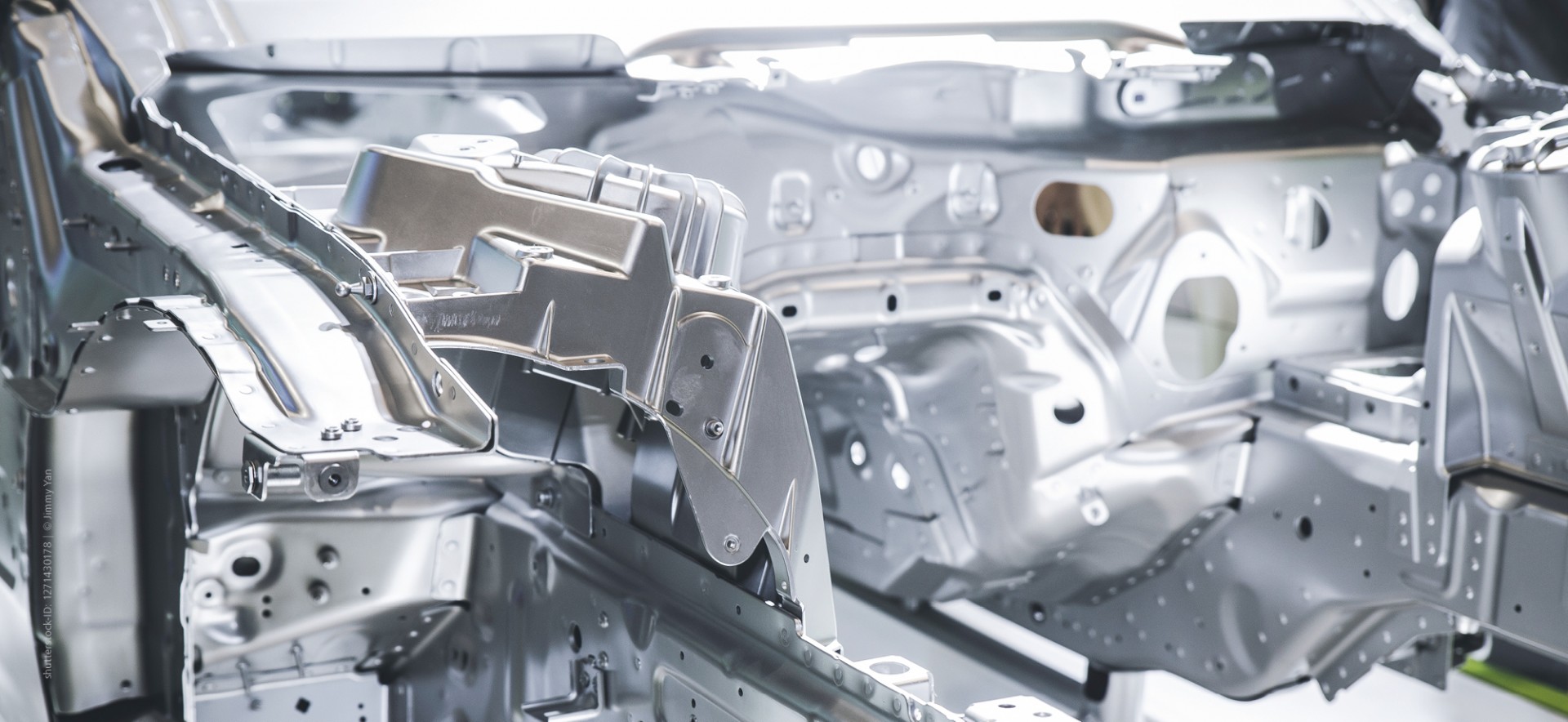

As a result of the growing use of lightweight metals and various high performance steels the fastening technology industry faces fresh challenges. It is an area in which friction element welding is gaining increasing ground. The manufacture of car bodies in particular calls for more intensive use of high performance materials. While this provides a better choice of materials and composites, the focus is now on which fastening solution to use – especially where aluminium and high strength steel in strengths above 1,000MPa need to be joined together.

One method of joining these two materials is friction element welding. Arnold is making increasing use of this assembly method for multi-material combinations. Working with BMW, Arnold has developed this fastener with several distinctive engineering design characteristics such as the drive, which has been designed to ensure that axial force and rotational speed can be optimally transferred. The fastener also features a tip geometry characterised by its wave like indentations that create the necessary stability during the process, while also reducing the necessary axial force. While the shaft has sufficient material to penetrate the cover sheet and, with the friction, to generate a welded joint. The element’s flange ensures that the head setting offers very little opportunity for corrosion to get a grip. Additionally, the head undercut enables space for the material rising from the cover sheet, which means that the head contacts the sheet.

The friction element welding process uses an element to join an aluminium sheet to high-strength sheet steel, as one example. The method uses the frictional heat that develops from the friction between the welding element and the high strength steel.

The process consists of four steps. In the first step, the hold down device is positioned onto the component, pressing the two metals together. The tip of the element is positioned on the aluminium cover sheet. The second step consists of penetrating this sheet. The fastener is applied at a set rotational speed and axial force, thus penetrating the aluminium cover sheet. The sheet becomes hot and softens. At the same time, the fastener displaces the cover sheet against the direction of assembly.

Once the fastener has completely penetrated the cover sheet and made contact with the high strength steel, the third stage can begin – the friction. The surface of the sheet steel is mechanically cleaned and the friction heats up the welding area. The sheet steel and the fastener both soften at this point. As a result the fastener is shortened. Once it has sufficiently shortened, the last stage of the process begins, the upsetting. The rotational speed is reduced to zero and the welding area is upset with high axial force while it cools down. The sheet steel and the fastener form a firmly bonded friction weld connection and the cover sheet is fastened in a positive and load carrying connection between the steel sheet and the head of the fastening element.

“The biggest unique selling point for friction element welding is that the method can be used for high strength sheet metals over 1,000MPa in strength. Few solutions in vehicle manufacturing can be used overall to join high strength steel and an aluminium sheet,” says Emanuel Heinle, research and development fastening systems, Arnold Umformtechnik GmbH & Co.

In terms of steel material, there is no strength limit. All that is necessary, depending on the thickness of the sheet, is to make sure that the materials can soften reliably during the friction process. According to Heinle, accessibility from both sides is also required. Since the direction of assembly is always from aluminium to steel, the fastener must be applied from the aluminium side. “In principle, the method is suitable for joining lightweight metals to high-strength steel. There’s no need to pre-form holes, and the method produces a very high-strength fastening,” explains Emanuel Heinle.

Friction element welding is appropriate, for example, in the production of car components such as the passenger compartment, which would suffer enormous stress in a crash situation, and the components used must therefore guarantee high strength.

The joint always consists of a base or foundation sheet consisting of high-strength steel, with a cover sheet of aluminium or other lightweight metal material. The process can be used for high strength steels such as hot formed 22MnB5 steel. The sheet thickness for the base sheet can range from approximately 0.80mm to 2mm, and the aluminium sheet can be between 1mm and 3mm thick.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.