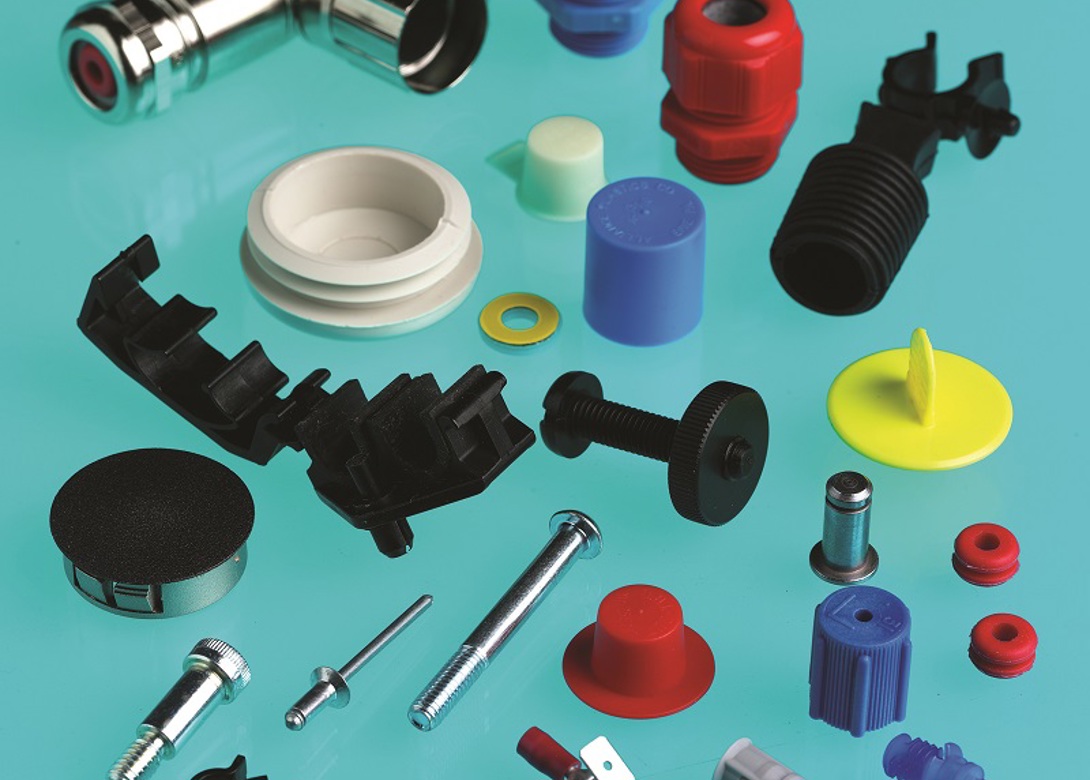

Successful design engineering is all about creating something that is greater than the sum of its parts. To do this you need to understand every nut, bolt and cable tie; and trust that it’s the best option for your application. While leading distributors offer hundreds of thousands of standard parts, sometimes it’s not enough. This is why Optimas provides its Bespoke Parts and Manufacture Service to help customers find the perfect solution.

Liam Marriott, technical manager of Optimas Solutions’ Components Division, explains how customers can add value through bespoke component design.

Whether you’re designing lighting solutions, medical equipment or the latest executive saloon, fasteners and c-class components will play a vital role in the reliability and quality of your product. In the majority of cases a simple standard part will be the best solution, offering the desired performance along with simple convenience. However, there are times when an application requires such specific capabilities that an obvious solution can’t be found in a catalogue. In fact, almost 35% of the business we process comes from customers who have requested specialised solutions.

This statistic comes as a surprise to a lot of people who assume that, as a distributor, we won’t have the flexibility to offer customised services. In reality the reverse is true. We have a team of engineers, CAD designers, application experts and product managers who work with a global network of manufacturers and suppliers – meaning that if you can imagine it, we can deliver it.

So, what’s the process for a bespoke component service, and how can it benefit your design?

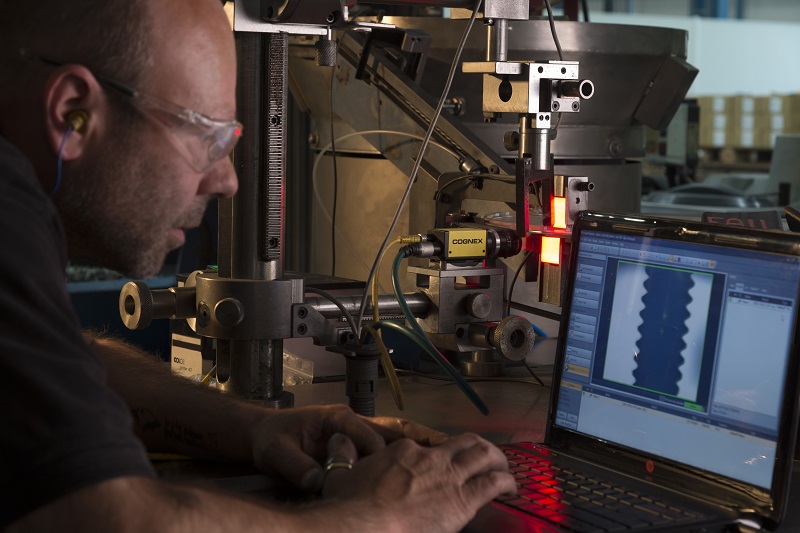

The process normally begins with a customer enquiry - asking one of our product experts for specification support. When a special request comes in our first priority is always to try and source an existing product, which is the most efficient solution if possible. Once all avenues have been exhausted, if a suitable component hasn’t been found, we will meet the customer face-to-face for a design briefing and create a Product Design Specification document.

From here the team compiles a series of concept solutions which can include line drawings, 3D CAD models and initial prototypes created using 3D printing and other rapid prototyping technologies. Once the final design has been tested and approved, we will work with a trusted supplier to produce the necessary tooling and start preparing the delivery of the first batch; a unique part number will then be created and kept on record to facilitate simple re-orders in the future. Of course, to guarantee excellence, the whole process is controlled by our ISO 9001 quality systems.

It stands to reason that the result of every project we undertake is unique, but we can broadly fit our solutions into two categories: customised or bespoke. Very often we discover that we can customise an existing part or combine standard components to deliver the performance the customer demands. Where this isn’t possible we will build the part ‘from the ground up’ and identify the right manufacturer to reliably deliver it.

For one customer, a successful manufacturer of industrial LED lighting solutions, we were able to develop an elegant, customised LED rivet design that helped to increase installation speed and create flexibility in the production line. The industry standard tapping screw that’s used to fix the LED circuit board to the panel required a manual process for installation, which demanded specialised tooling. Our team was able to modify an existing push fit rivet to retain to a standard LED PCB; adjust its material construction to improve UV resistance; and also design in a solution to enable disassembly with a single screw driver in the event of maintenance.

As a result, the customer was not only able to speed up the production line, but during busy periods it was possible to move the process to ‘overflow workstations’ that weren’t equipped with any additional tooling.

In another example, we worked with a designer of high-end car conversions. Here we created a number of truly bespoke parts, which were able to support them in creating ergonomical solutions that were in keeping with the superior finish and aesthetics of luxury vehicles. One such example was a ‘snap-on’ hand knob, used to aid with steering. We employed an overmoulding finishing process to make sure the part had a long-lasting, quality finish and that it would be comfortable in the hand.

As we operate a personal service based on product expertise and an understanding of our customers’ industries, we are always keen to offer support throughout all stages of specification. Only when we are sure that our design service is the best option for a customer will we suggest it. This means that when we do begin the process we are able to show the customer how the end result will provide tangible advantages to their product, to their business and to their customer. The benefits of bespoke component design differ from application to application, but to learn how you might gain a performance enhancement it’s always worth getting in touch with our team to see how we can help.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.