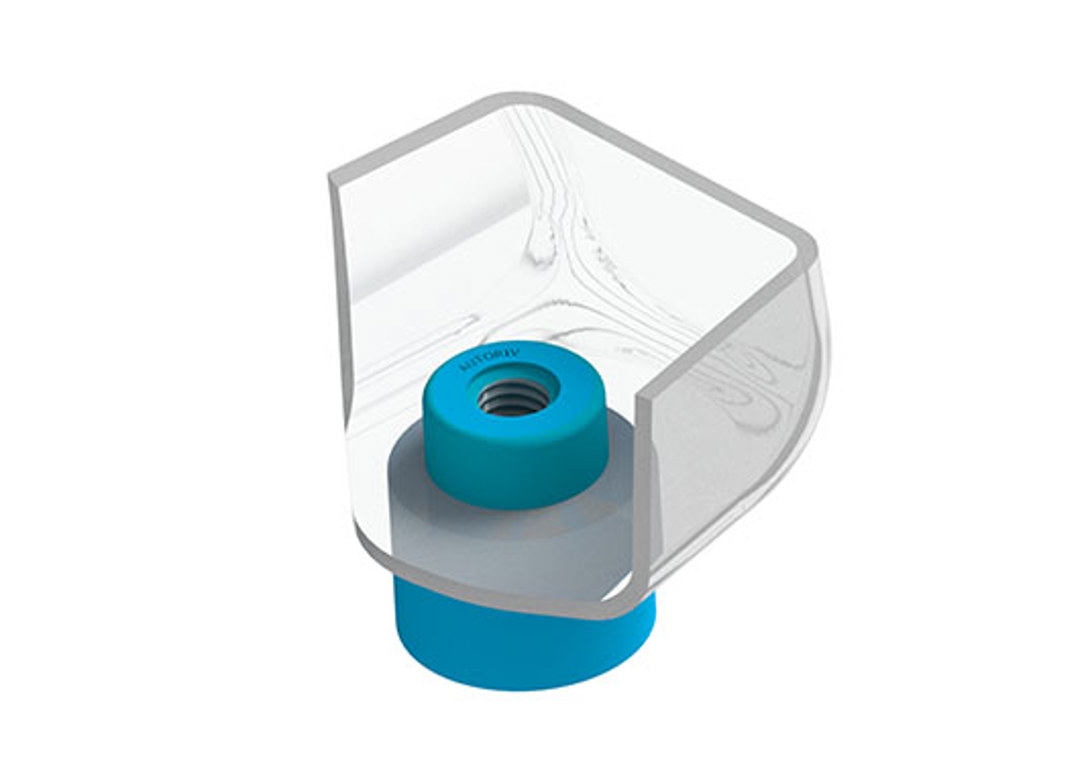

Setting high strength connections in aluminium profiles requires special solutions. The Regensburg-based machine manufacturer AUTORIV offers a setting process for such applications that has also proven itself in automated use - the combination of rivet nut and washer.

The rivet nut washer combination is often used in practice in the field of eMobility, for example in the battery trays of electric vehicles. Also with crash elements, module carriers, as well as in commercial and agricultural machinery. Furthermore, the combination is often used as a stop surface and is also suitable as a chemical insulator.

The rivet nut washer combination is generally preferred for high strength screw connections. It offers advantages when used in extruded profiles and internal high pressure bodies. This combination is also optimally used in hard to reach places, with very limited installation space and in components with an undercut or overlap.

The establishment of such a connection requires three work steps and is therefore quite costly. With the automated use of the rivet nut washer combination, these processes, i.e. two press-in processes and one riveting process, can be carried out in a single work step. The streamlining of the manufacturing process therefore offers some potential for cost savings such as shorter lead times and lower logistics costs.

AUTORIV offers special solutions for special applications. For example, individual adjustments to the connecting element or the special tool environment can be made. The dimensions of the rivet nut and washer can be designed variably, optimised for the application at hand. Other materials, strength classes and coatings are also possible on request.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.