When it comes to fastening mechanical joints, welding is not always an option as the materials the fastener must be mounted to aren’t always weldable. Against this background, Böllhoff has teamed up with the DELO Company to develop an innovative fastening system: ONSERT®. The idea behind it: adhesive bonding when welding is beyond possible.

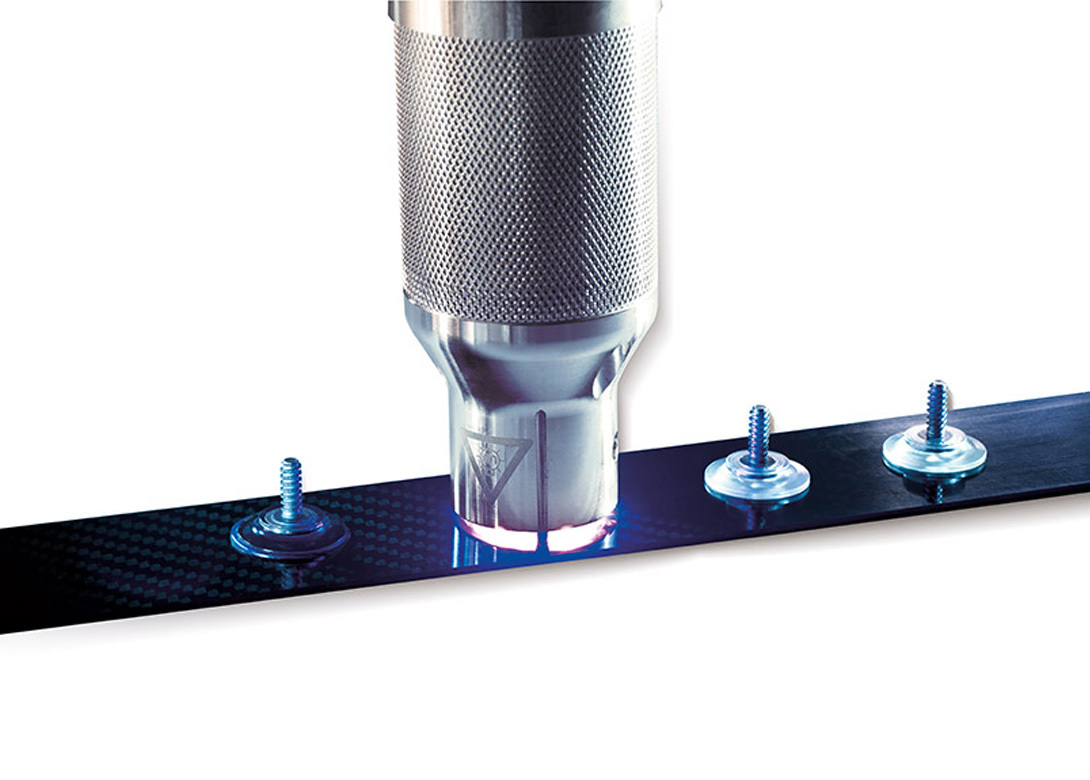

Fastening elements with a socket made of transparent plastic are bonded to the customer component using a light-curing adhesive. The most important aspects of ONSERT® technology are the short cycle times, the material-friendly process and the flexibility regarding the fastening elements.

Generally, all geometries which can be produced through injection moulding can be realised. This includes screwed connections on plastic mouldings, detachable and non-detachable snap connections or adhesive SNAPLOC® fasteners, all of which can be applied to materials such as CFRP, FRP, glass, lacquer, cathodic dip coating, plastic such as PC‑ABS, PA and blends.

The ONSERT® technology can be employed in diverse ways in different industries. Especially in aviation as well as in the automotive industry, where lightweight construction plays an important role and fast bonding without loss of performance is vital.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.