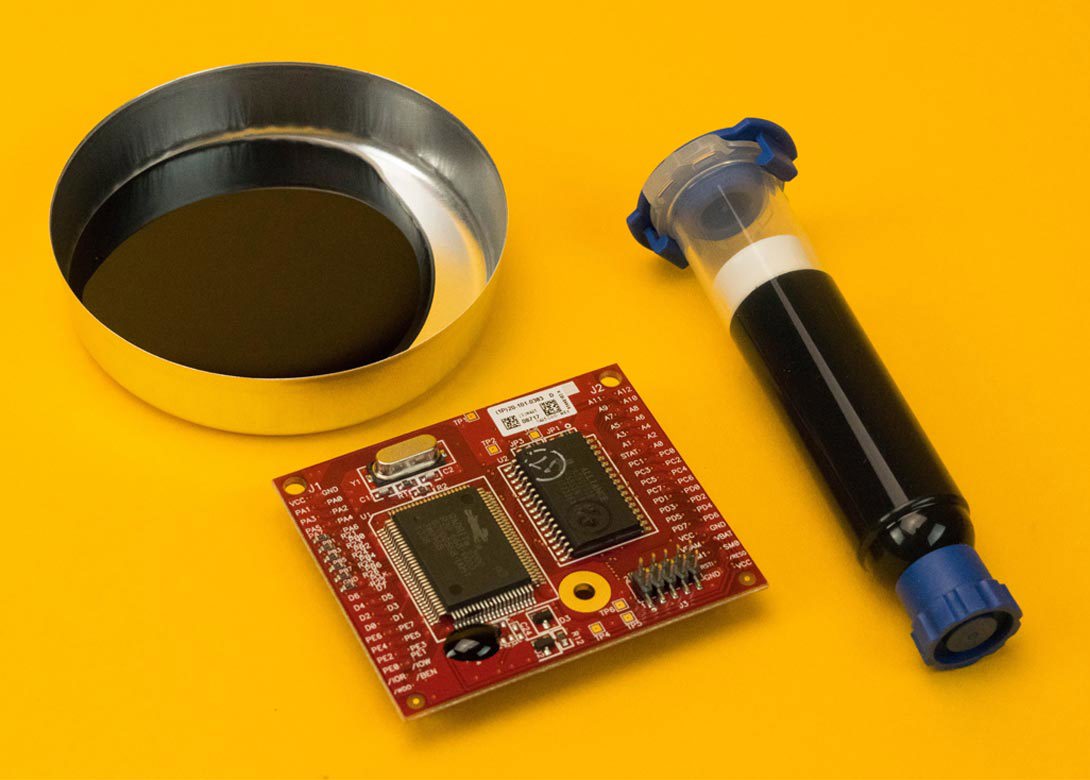

Master Bond EP17HTND-CCM is a new single component epoxy that is not premixed and frozen. It is more convenient to handle, apply and store than typical two component glob top systems.

This black, heat curable compound has a flowable paste consistency ideal for glob top, chip coating and bonding applications. EP17HTND-CCM meets NASA low outgassing specifications and is serviceable from -80°F to +600°F [-62°C to +316°C]. This adhesive forms high strength bonds to a wide variety of similar/dissimilar substrates such as metals, ceramics, plastics, composites and various circuit board materials.

EP17HTND-CCM is thermally conductive and electrically non-conductive even upon exposure to hostile environmental conditions. EP17HTND-CCM has a high volume resistivity of more than 1015 ohm-cm at 75°F and over 1012 ohm-cm at 400°F. Its thermal conductivity is 9-10 BTU•in/ft2•hr•°F [1.4423 W/(m·K)] at 75°F. Also noteworthy is its ability to resist many chemicals including acids, bases, salts, fuels, oils and many solvents.

Formulated for various electronic applications, EP17HTND-CCM cures readily in 1-2 hours at 350°F [175°C] with a relatively low exotherm upon curing. It can be dispensed from a syringe, either manually or with an automatic dispenser. Master Bond EP17HTND-CCM is available for use in common size syringes ranging from 10 cc to 30 cc. For storage simple refrigeration at 40-45°F is recommended.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.