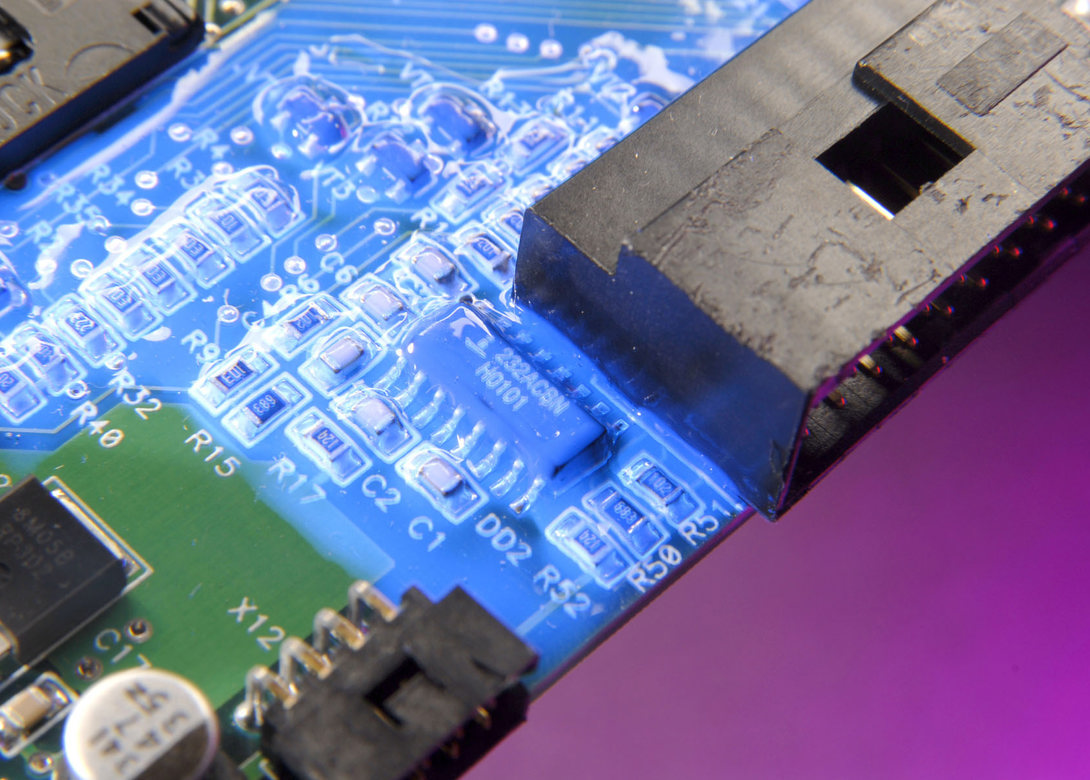

Adhesives supplier Intertronics has introduced new Dymax Dual-Cure 9771 Light and Moisture-Cure Conformal Coating to its product range. This low outgassing material is the first conformal coating that meets ASTM E595 and Mil-Std 883 Method 5011 and is therefore suitable for the aerospace and defence markets in applications including missile, satellite, and space critical printed circuit board (PCB) assembly.

Dual Cure 9771 is a reworkable coating, specially formulated to cure with light, with a secondary moisture cure mechanism to ensure all material, including any that flows underneath components on a PCB, fully cures. It is engineered for coating thickness of up to 0.02mm, has a low ionic content and meets low outgassing standard test ASTM E595, meaning it provides a cleaner PCB during extreme conditions. This testing is run is run at 125°C under a 5 X 10-5 Torr vacuum for 24 hours and total weight loss, collected condensable volatile material and water vapor recovered are measured.

Under heat or vacuum, materials can emit gas in a process known as outgassing. This can be a concern to businesses as it could indicate decomposition or structural change in a material, contaminate a surface that must remain clean to retain its electrical properties, contaminate the environment the part is in or indicate corrosion, or other surface weakening mechanisms. ATSM E595 is a standard test method to determine volatile contents of materials under vacuum.

Dymax 9771 passes the following Mil-Std 883 Method 5011.7 tests: thermal stability and filler content via thermogravimetric analysis, specific ion content, total ionic content, hydrogen ion content (pH), and volume resistivity. This means military and defence product manufacturers finally have a compliant conformal coating product to protect their electronic assemblies.

“Conformal coatings are a well established method of protecting PCB assemblies without adding excessive cost or weight,” said Ben Swanson, sales manager of Intertronics. “Dymax dual cure conformal coatings are easy to apply and cure, typically in seconds. The secondary cure mechanism ensures complete cure in applications where shadow areas on high density boards are a concern, which typically takes two to three days dependent on the application.

“Adding this product to our portfolio means manufacturers of missiles, satellites, and space-critical PCB assemblies have a material that meets these standards, while offering the desired features like corrosion, temperature and humidity resistance, and the industry standard blue fluorescing tracer that allows in-line quality inspection before and after cure,” added Swanson.

Mil-Std 883 method 5011 is a military test standard that establishes uniform methods, controls, and procedures for testing microelectronic devices. It includes procedures to test electronic devices for military and aerospace electronics systems, including mechanical, electrical, and environmental tests to determine quality and reliability, to ensure the product is suitable for its intended end use.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.