Clamping pins have become the tried and tested method for securing the fixtures and jigs used in aircraft construction, as they enable quick and easy loading and unloading of large parts. However, in their traditional designs they are not without flaws, which prompted WDS Component Parts Ltd to look for improvements.

Throughout the aerospace industry, accuracy is key. Removable jig plates make it easy to replicate processes from one structural part to another. Also when the parts are loaded onto a jig bed they can be quickly and securely clamped in position.

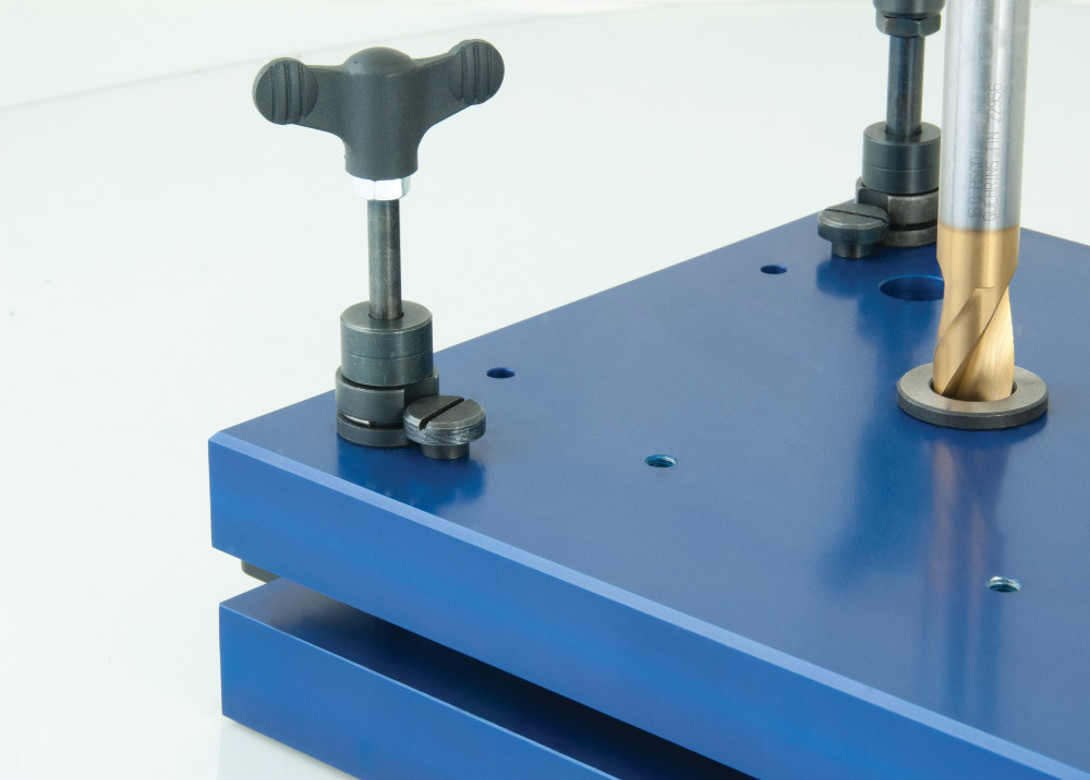

The method for loading and unloading large jigs is to combine precision-ground retention bushes with clamping pins. However WDS found there are inefficiencies such as traditional clamping pins becoming dislodged when the jig is being moved resulting in a lost pin. While there are currently captive clamping pins available from other manufacturers there were complaints that these pins suffered from a leaf spring glitch at times, again resulting in the pin becoming lost. This is why one manufacturer asked WDS to develop a retained clamping pin design.

WDS say they have developed a design that offers several advantages. The leaf spring and notch has been designed so that the spring is inherently ‘self-retained’. The pin can be re-used on multiple assembly jigs with no risk of the spring becoming dislodged and lost. This reduces wastage during assembly and helps to maintain efficiency productivity. The collar is mobile on the pin when it’s delivered, this allows the end user to modify the shaft length to fit the depth of the fixing plate – once the ideal length is found the collar can be welded in position or the shaft can be cross drilled and pinned.

WDS state that flexibility is also present at the point of specification. With other clamping pins on the market there is typically a single handle choice. This is can be unsuitable in many applications where there are space restraints. WDS offers a choice of four handles as standard with its range: a traditional T-handle, a steel hand knob, a plastic handle or an adjustable torque knob. There is also an option to specify a bespoke handle from the entire WDS range, as well as the option to order a clamping pin with no handle fitted. All options are available ‘out of the box’, meaning that the pins are delivered ready to go.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.