BUMAX has been chosen to supply more than 11,000 high strength and corrosion resistant fasteners for the world’s largest telescope ELT - Extremely Large Telescope - presently under construction.

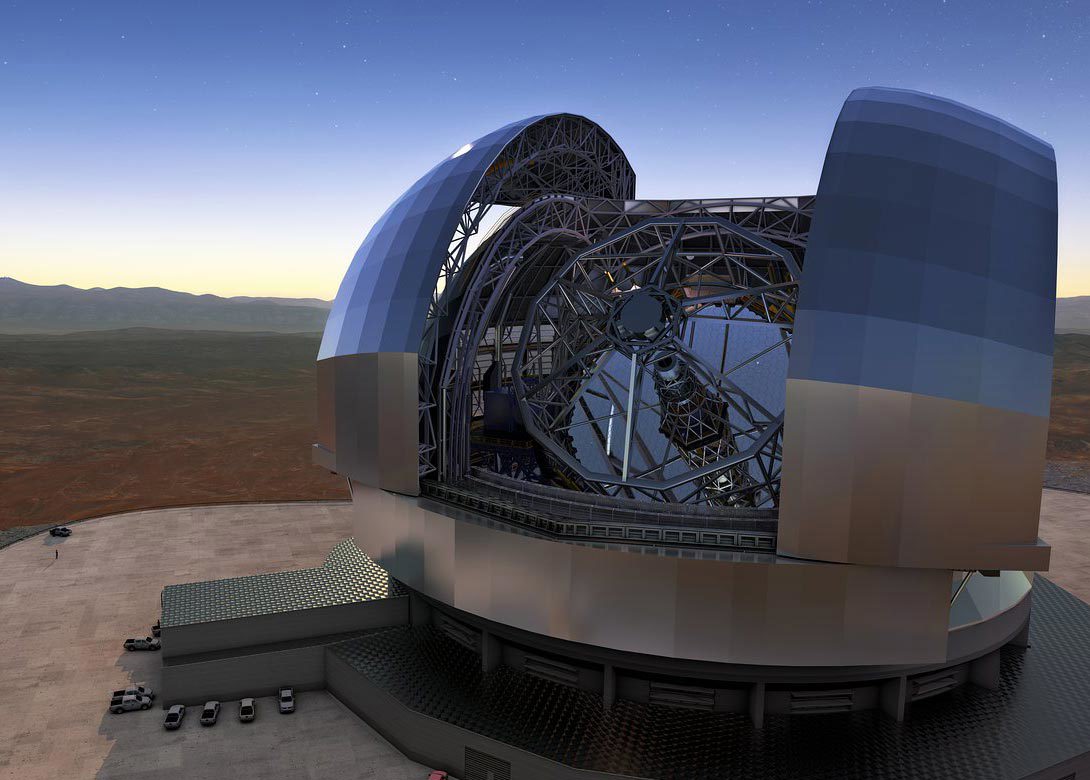

The €1 billion ELT will become the world’s largest telescope when it becomes operational in northern Chile in 2024. It is a reflector telescope collecting universal light using a 39m curved mirror, which is 3 times the area of the next largest telescope.

Such a giant mirror is much too large to be made from a single piece of glass, so it will consist of 798 individual hexagonal segments, each measuring 1.4m across and driven by electrical motors for fine tuning. The segments will work together as a single huge mirror to collect 100 million times more light than the human eye.

BUMAX fasteners are used to fix the nearly 800 telescope mirrors to all the segment supports. 12 pieces of 10mm long BUMAX 109 M6 bolts per segment are used for more than 900 segments in total (the 798 support segments plus an additional 133 segments for a continuous swapping process to allow the mirrors to be cleaned and coated while the ELT stays operational).

Customised bolts required special tools

The ELT is presently under construction by the VDL ETG Projects in the Netherlands. Michael Evers, project manager at VDL ETG said: “Standard stainless steel bolts lack the strength required for the ELT. We required a 10.9 strength bolt, and with the corrosion resistance of stainless steel. BUMAX offered us the perfect solution.”

“The high strength BUMAX 109 fasteners prevent damage to the mirror segments, which is very costly. Their corrosion resistance is also essential as the fasteners are sometimes open to the elements and will reduce future maintenance requirements,” continued Michael.

The bolts are a customised product that have been coated with a special surface treatment and require special tools to manufacture. Patrik Lundström Törnquist, managing director at BUMAX explained: “This order is yet another testament to BUMAX being able to provide the very best fasteners for the most demanding applications. We have also been trusted with supplying fasteners for the CERN accelerator in Switzerland, satellites, and submarines.”

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.