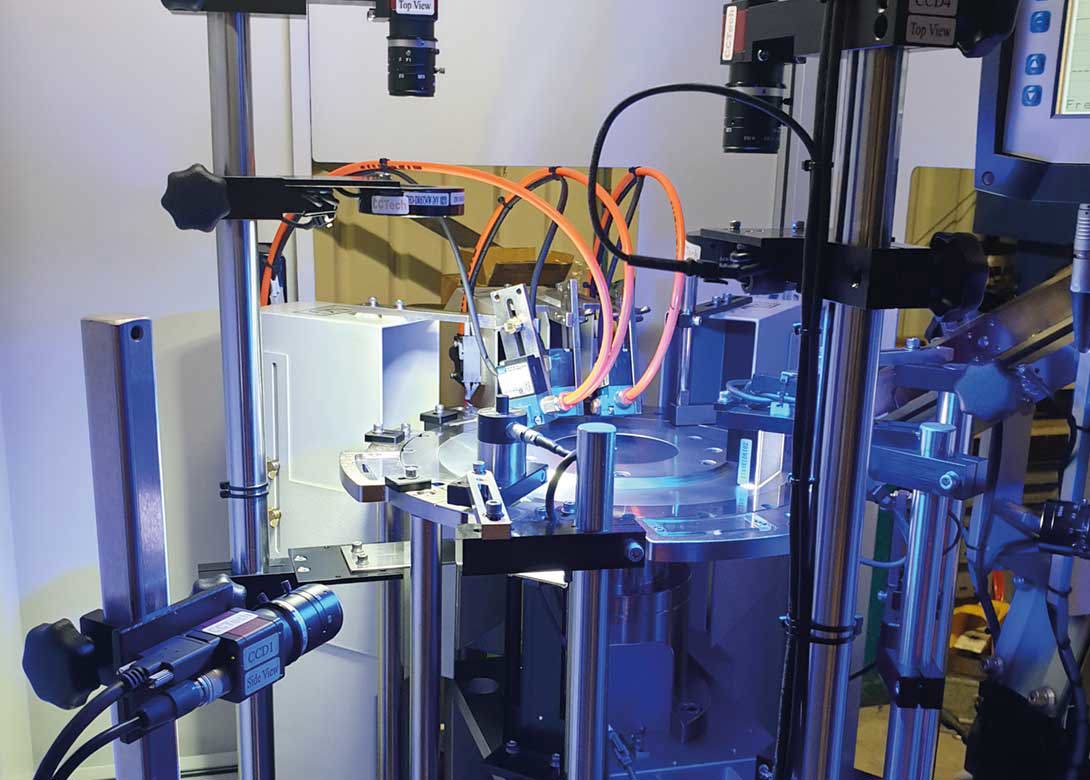

CBM member and cold forming manufacturer, Clevedon Fasteners Ltd, has taken delivery of its most advanced optical sorter yet. The state of the art machine has four cameras and an Eddy current checking station, which can be used for comparative testing – ensuring parts are to the correct heat treatment specification.

As Clevedon’s sales of threaded parts in general continue to increase, with clinch studs in particular, the Sutton Coldfield company wanted to provide customers with a greater level of security regarding the product’s property class – rather than simply supplying a second party heat treatment certificate.

The cameras on the optical sorter not only check for contamination and dimensional inaccuracies, but also incorrect aesthetic elements such as misshapen heads, clinch ring defects, and colour – as well as lettering and other non-dimensional problems.

The parts that pass the camera and Eddy current scrutiny are fed directly into the dispatch boxes ready for shipment to the customer. This ensures no post-sort contamination. The combination of these technologies ensure Clevedon moves nearer to its goal of defect-free products, and enables it to build upon its already impressive quality record.

Last year Clevedon celebrated its 80th anniversary, having been founded by Bert Godwin and Fred Wood as Clevedon Rivet and Tools in 1939. The company developed carbide steel cold forming tooling and ventured into aluminium alloy rivets, which were installed on, amongst other wartime aircraft, the iconic Supermarine Spitfire.

Today, Clevedon Fasteners specialises in the manufacture of cold formed components for use in the commercial and automotive markets worldwide. From its roots in the aircraft industry it has always maintained the disciplines of technical competence, combined with outstanding customer service, to forge a reputation for quality, reliability and rapid response to customer needs.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.