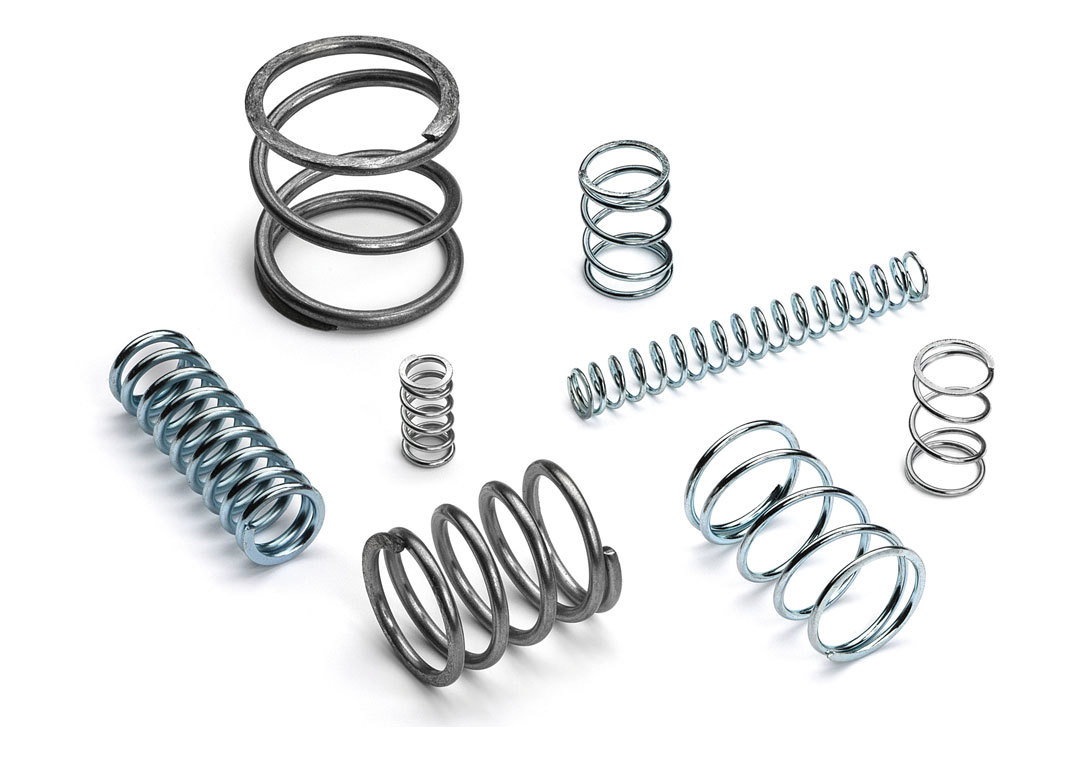

An extensive range of springs

17 June 2016

Lee Spring Ltd is constantly building its extensive range of compression springs, both ex-stock for urgent delivery and in custom designs, to suit manufacturing across all areas of industry. This includes the Bantam™, HEFTY™ and LeeP™ series.

Bantam™ mini springs are available in ranges from 0.64mm outside diameter and in cobalt nickel alloy. They can be use in medical devices, precision instruments, aerospace, and many other control/process/security devices.

Mainstream die springs are also available in the HEFTY™ series, which feature a high performing round wire section, and Lee Spring says offer a like-for-like performance at typically 1/3 to 1/2 the cost of traditional rectangular wire units. They are extensively used in non-die applications where their performance/cost profile enables users to also benefit from their high-quality and reliability.

In a similar vein the LeeP™ series of plastic composite compression springs combine the strength of metal with the special attributes of high performance engineered thermoplastics. This approach maximises spring rates and cycle life with high strength to weight ratios, along with high corrosion and chemical resistance. In addition of course they are non-magnetic, non-conducting and non-contaminating, as well as being recyclable and RoHS/REACH compliant.

Other specialist compression designs include AISI 316 stainless Lite Pressure™ variants for use where a low pressure and large diameter spring is required to spread force over a relatively large area, for example in relief/check valves, electrical contacts, toys, syringes, etc.

Since the specification of compression springs is often a matter of physical testing – and for the convenience of one off frequent users in development or service sectors – Lee Spring also has available a set of kits containing a selection of different sizes of compression springs in music wire or stainless steel.