Accu has developed a new range of captive washers, specifically designed for use in assembly work within the industrial, aerospace, military and automotive markets to offer a reliable retaining solution.

A captive washer is a type of retaining washer commonly used to securely fasten screws within an assembly, affording a permanent hold. Unlike a conventional washer, which is designed to aid in fastening a bolted component or a screw to a female threaded part, the captive washer acts as a retainer to ensure there is no risk of parts dropping free, causing foreign object contamination or fastener loss.

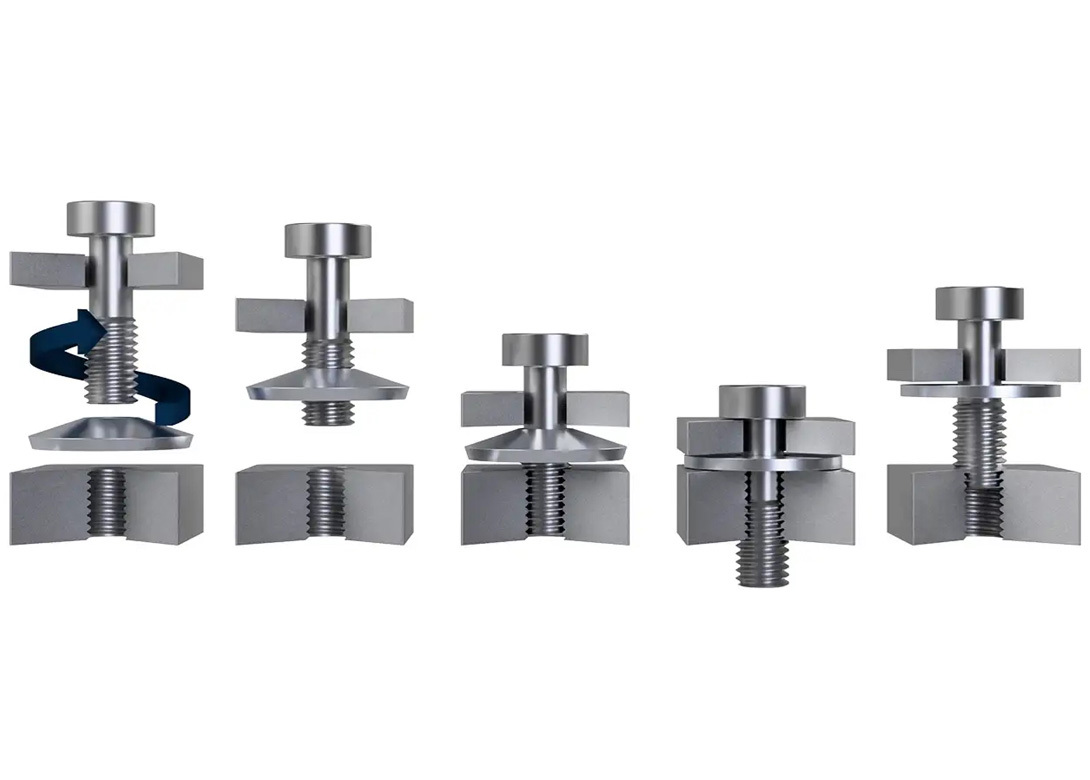

Accu’s new captive washer is manufactured to a new UK/ EU registered design, with clear advantages over the standard push on style, or flat threaded disc. The washers are designed to be as easy-to-install as standard threaded washers, but with the permanence of a push-on retaining washer. Accu states the new captive washers simplify assembly by a thread-on construction and, unlike push-on washers, they can even be installed upside down with no loss of function.

The captive screw or captive bolt is inserted through a clearance hole in the panel, with the captive washer being screwed onto the end of the thread and over to the waisted shank, also commonly known as the captive shank. This action holds the screw or bolt in place temporarily, allowing for removal if required, while still retaining all parts to be fastened into one assembly. Once the panel is tightened into place, the washer deforms and becomes permanently attached to the screw, ensuring that they cannot fall out when the panel is removed from the assembly.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.

Don't have an account? Sign Up

Signing up to FastFixTechnology.com enables you to manage your account details.