Master Bond Supreme 11AOHTMed is a two component epoxy featuring thermal conductivity and electrical insulation – a system which fully passes ISO 10993-5 testing for non-cytotoxicity and is recommended for bonding and sealing in medical device applications.

Supreme 11AOHTMed has reliable electrical insulation properties with a volume resistivity exceeding 1014 ohm-cm at 75°F (23.9°C). It also exhibits thermal conductivity of around 0.58 W/m/K – 0.72 W/m/K. The system provides high bond strength properties with a lap shear strength of 3,200 psi – 3,400 psi, a tensile strength of 7,000 psi – 8,000 psi and a compressive strength of 20,000 psi – 22,000 psi. This toughened formulation is designed to withstand thermal cycling and offers a wide service temperature range from -112°F to +400°F (-80°C to 204°C).

Supreme 11AOHTMed cures at room temperature in 24 – 36 hours, and faster with heat, in 1 – 2 hours at 200°F (93.3°C). To optimise the epoxy properties, Master Bond recommends overnight cure at room temperature, followed by a post cure at 120°F (48.9°C) – 150°F (65.6°C) for 2 – 3 hours or preferably longer.

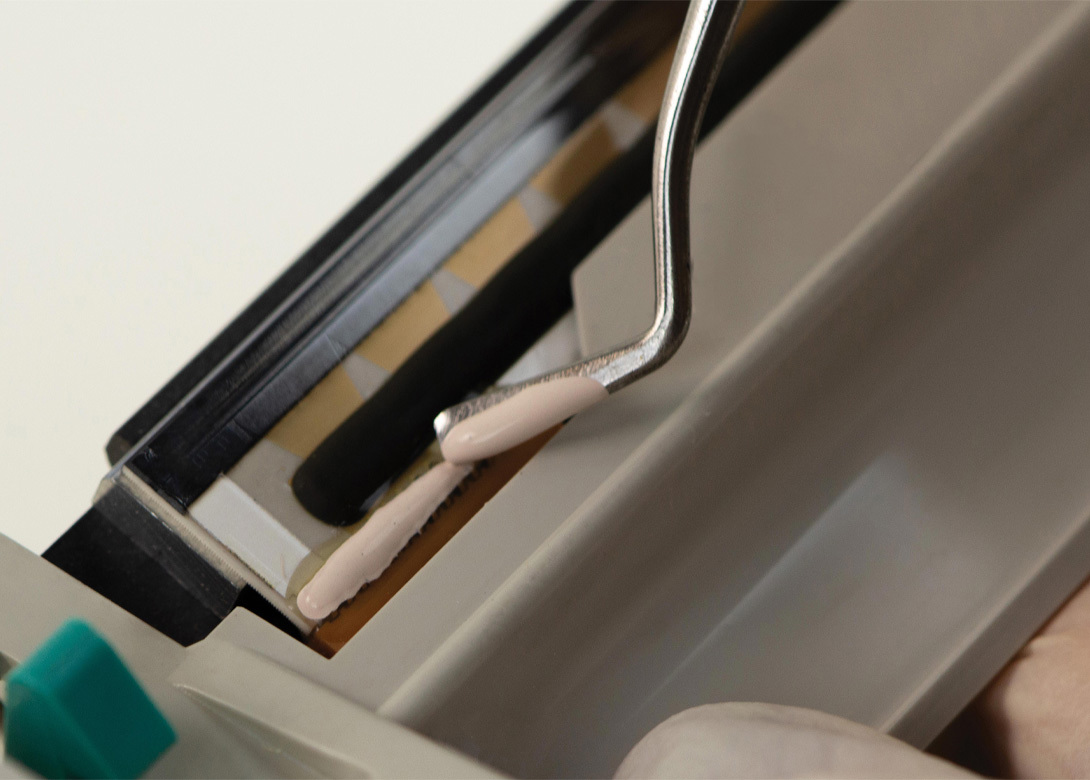

The epoxy bonds well to a wide variety of substrates including metals, ceramics, glass, rubbers, and many plastics. This epoxy system has a convenient 1:1 mix ratio by weight, with the mixed material being a thixotropic paste. To eliminate the need for manual measuring and mixing, it can be packaged in double barrel cartridges for gun kits. It is also available in standard jars and cans, ranging in size from ½ pint to gallon containers.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.