fischer offers a wide range of chipboard screws for ideal connections between chipboard and other wood materials. The innovative fischer PowerFast II screw offers a particularly extensive range of applications with its suitability for any wood on wood and wood on metal connections and for approved loads in plastic plugs by fischer, thereby covering a wider range of applications compared to traditional chipboard screws.

fischer’s chipboard screws with their European Technical Assessment (ETA) are particularly quick and easy to use, with a low expansion effect and a high load-bearing capacity for connecting chipboard and other wood materials – be it while fastening and tightening timber elements or planking, skirting boards and door or furniture fittings. Multiple available variants cover a versatile range of furniture and interior construction applications.

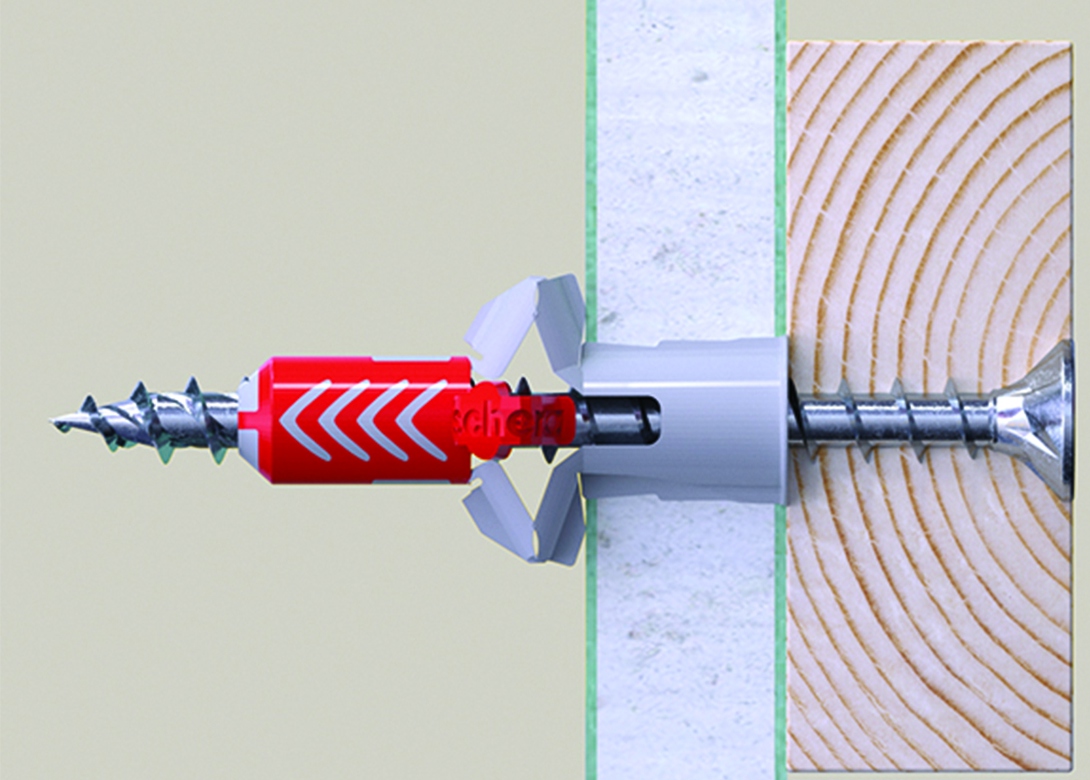

The innovative fischer Power-Fast II chipboard screw offers the advantage of covering a particularly wide range of applications. It is suitable for use in soft and solid wood as well as various panel materials, with low edge spacing and with metal fittings. Its innovative screw geometry enables secure connections between wood components or wood and metal and can be used for approved loads with plastic plugs such as fischer’s DuoPower.

The Power-Fast II can also be used in load-bearing wood constructions in order to connect solid wood (softwood and hardwood), laminated wood, laminated beam timber, board plywood, veneered laminated timber as well as similar glue laminated wood components and wood material boards. It is also suitable for connecting metal fittings, brackets, joist hangers and other components to wood materials.

With its quick bite and fast processing, the PowerFast II speeds up the installation process and delivers high-precision results. With its three ribs, the screw tip provides a quick bite with a pre-drilling function, allowing quick insertion of the screw without splitting the workpiece. The innovative core milling geometry allows precise milling and convenient swarf removal, enabling low edge and axial spacing. Special shaft ribs combined with the core milling geometry noticeably reduce the insertion resistance, requiring less battery life and less effort to process. The higher thread pitch further reduces the time it takes to insert the screw.

Its electrogalvanised, blue passivated coating does not contain any Chromium (VI) and is therefore environmentally sound. The high performance wax coating additionally reduces the screw-in torque, ensuring a longer battery life while requiring less effort to insert the screw. The new bit exchange system saves additional time by reducing the number of bit changes to just two exchanges in the diameter range of 3mm - 6mm.

Using the PowerFast II additionally enhances the look and feel of surfaces, as the screw features a special geometry beneath the head with an optimised double cone and mill pockets that prevent scratches to wood surfaces and damaged metal fittings. With variants including countersunk and pan heads, various sizes and different drive and thread types, the PowerFast II offers even more flexibility.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.