Bolt inspections and retightening routines are common and reoccurring across several industries. Here, Strainlabs AB in collaboration with ABB gives an overview on the natural causes to why bolt preload changes over time.

Settlements & relaxationStrainlabs is turning bolts into an IoT (Internet of Things) solution. The system is CE marked and available on the market for implementation into standard bolts. Several factors affect the achieved preload in a bolted joint. This includes friction, lubrication, tool accuracy and the human factor. In addition, preload also changes over time due to several natural reasons which, altogether, can have a major impact on safety.

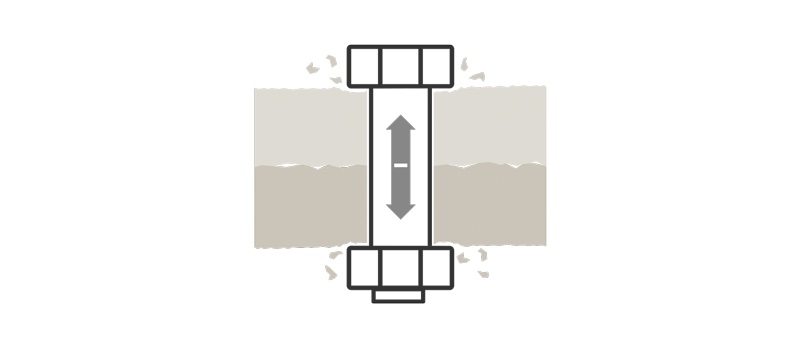

Thermal contraction/expansionSettlements, relaxation, and creep occur over time in all materials. The softer the materials, surfaces, coatings or paint in the joint, the more significant the loss of preload is over time.

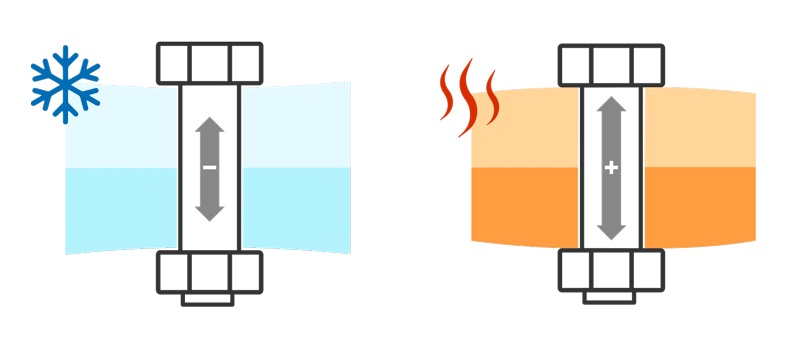

All parts in a bolted joint expand and contract due to temperature changes. Materials in a joint can also have different coefficient of expansion, which may result in both increase or decrease of preload.

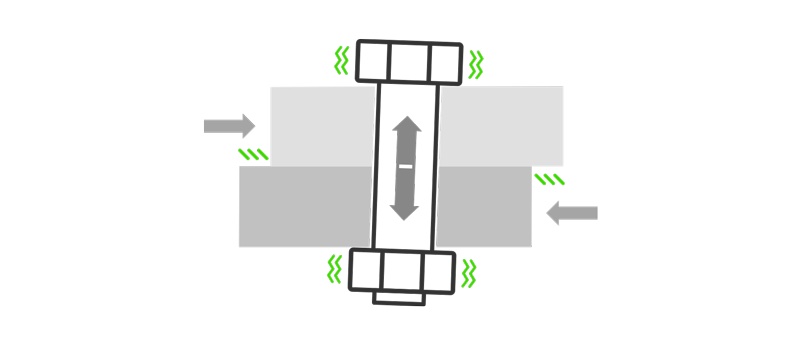

When slipping occurs between contact surfaces, it may cause a rotation of bolts and nuts in the untightening direction, so called self-loosening. Dynamic workloads, impacts and vibration therefore have potential to affect the preload.

Dynamic loads & vibrations

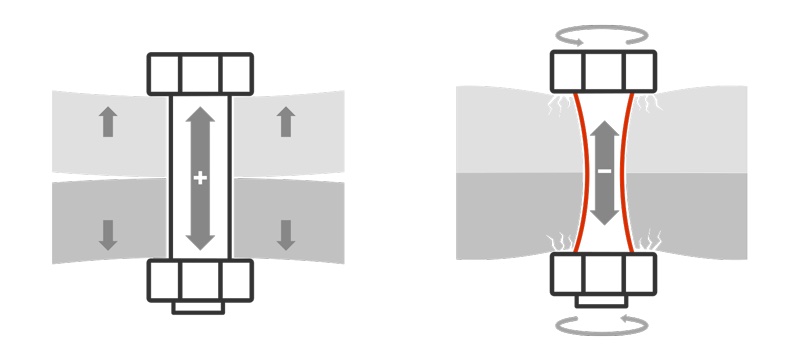

If the working load is higher than the preload in a bolted joint, the parts may separate and the joint loses its function. If a bolt is overtightened, it can lead to yielding or the joined parts becoming permanently deformed.

Separation of parts and yielding

“It’s not realistic for the industry to create exact models of the mechanical behaviour over time for every bolt, with the aid of laboratory environments or calculations when there are so many parameters affecting and interacting. The industry has long sought after a way to assess the safety of a bolted joint, which is done when you measure its preload,” says Csaba Madru, CEO at Strainlabs.

“Bolts are an established solution for assembly, mainly because of its high strength and its flexibility in terms of simple disassembly. Industries are today used to spending time on bolt inspections and we see great potential in this type of more advanced sensors able to give correct mechanical data during a relatively long period of time,” added Peter Isberg, digital lead at ABB Motion.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.