Specialinsert Srl, established in 1974 initially as a distributor of fastening systems, is celebrating its 40th anniversary with the opening of a brand new and modern headquarters in Turin, Italy.

Over the past 40 years, through the management of the founders and now the second generation, Specialinsert has strengthened its production of fastening systems. Through investments in its staff and export department, the company has been able to expand its presence in international markets around the world. Also, thanks to its commitment to continuously investing in the research and development of new products, the company has the ability to target specific markets with unique products – especially emerging markets.

For instance Specialinsert has already developed, patented and launched several products for the composites sector.

Specialinsert has offices, warehouses and a manufacturing plant covering over 5,100m2 – in three units located in Turin, Milan and Maerne di Martellago (Venice). All are equipped with their own research department, test laboratory, and a flexible and skilled sales network operating on the domestic and foreign markets.

Due to the hard work of its research and development department, Specialinsert is able to constantly offer new products to the market. Two recent innovative fastening systems include the KEEP-NUT™ and the MASTER-PLATE™.

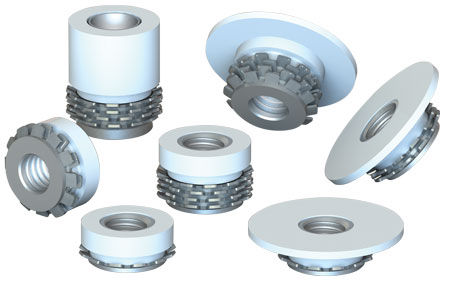

KEEP-NUT™

KEEP-NUT™ is a press-in insert with mechanical anchoring to create threaded seats on panels made of marble, granite or other stones, as well as composites, carbon, Corian®, HPL, glass and others solid materials.

KEEP-NUT is manufactured in stainless steel and is made of a threaded bush, with a set of toothed spring washers, and a plastic ring holding the parts together. It comes in different lengths, with or without flange, to fit several different panel thicknesses. KEEP-NUT can be installed quickly since the user simply needs to drill the material with the correct hole diameter and press-in the insert. The KEEP-NUT can also be customised with different versions and sizes, to match customer needs.

KEEP-NUT is manufactured in stainless steel and is made of a threaded bush, with a set of toothed spring washers, and a plastic ring holding the parts together. It comes in different lengths, with or without flange, to fit several different panel thicknesses. KEEP-NUT can be installed quickly since the user simply needs to drill the material with the correct hole diameter and press-in the insert. The KEEP-NUT can also be customised with different versions and sizes, to match customer needs.

*Results achieved at Specialinsert lab under optimal conditions

The KEEP-NUT insert is specifically developed to fasten ventilated facades, wall-coverings, décor and interiors, furniture, kitchen and sanitary elements, as well as a variety of other applications.

Specialinsert believes the KEEP-NUT insert has several advantages compared to other fasteners for stone and solid materials. The preparation needed is just a cylindrical hole – an undercut hole is not required – which means that standard tools can be used. In addition, assembly by pressure is fast and easy and does not require use of any additional resins or adhesives. The KEEP-NUT can be used for hidden assemblies without any protruding parts, facilitating the handling and installation of a variety of materials.

In use, the spring washers are engaged by axial force, acting radially against the hole walls due to the bending and pressure – avoiding the release of the insert from the hole. In addition, the internal thread does not run completely through the bush, which prevents extraction as a result of the use of an excessively long screw.

Specialinsert has carried out laboratory tests in its own facility, using optimal conditions, which underline the KEEP-NUT’s high pull-out strength performance – highlighted in the table (right).

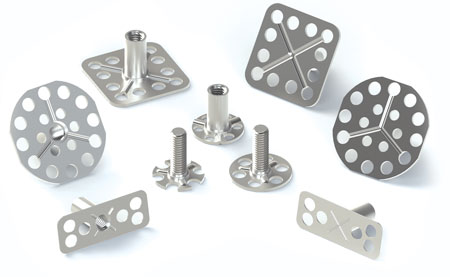

MASTER-PLATE™

The wide variety of combinations between the base plates and fastening elements offer a wide range of possibilities to technicians and designers.

MASTER-PLATE is made of a base plate that is available in a range of different shapes and dimensions (round, square, rectangular) and a fastener element – a threaded bush or stud – which can be manufactured in zinc plated steel or stainless steel AISI 316.

MASTER-PLATE is 100% made in Italy and thanks to its ‘just in time’ production process it can be delivered in a very short time.

"Thanks to the knowledge and expertise of our technical sales agents, we are able to provide a wide selection of fastening solutions, standard or tailored to customer needs, which can provide innovative solutions for new fastening applications.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.