The planned ban on petrol and diesel car sales by 2040 will change the automotive industry landscape, however companies like tesa say they are already positioned to support manufacturers. Whilst the announcement of petrol and diesel vehicles being banned in Britain by 2040 was met with scepticism in some quarters, it cannot be denied that change is on the horizon, especially when environment secretary Michael Gove is insisting there is “no alternative to embracing new technology”, due to the damage harmful emissions are causing to the environment.

There will be many implications of a mass shift away from fossil fuel, but signs pointing towards a genuine electric future began gathering pace even before last month’s ban announcement. Registrations of plug-in cars have increased from 3,500 in 2013 to almost 61,000 at the beginning of May 2017, showing consumers were already embracing alternative fuel-powered vehicles.

Competitive racing is often at the forefront of vehicle advancement and this year has seen a spike of interest in Formula E, which recently added powerhouses Mercedes and Porsche to the likes of Renault and Jaguar among its ranks. Carmaker Volvo also announced they plan to be manufacturing only electric or hybrid vehicles by 2019 and Lars Tomsen, advisor to major automotive groups, has claimed “anyone who doesn’t make the change now will experience what Nokia did with Smartphones or Kodak with digital photography”.

Even Ben Van Beurden, CEO of Royal Dutch Shell plc, recently told Bloomberg the move to electric must happen “fast” and that the next car he buys will be an electric vehicle. “The whole move to electrify the economy, electrify mobility in places like northwest Europe, in the USA, even in China, is a good thing,” he said, “We have to continue to reinvent”.

Adhesive tape specialist tesa is one company that says it’s ready to support manufacturers in finding solutions to meet the needs of this dramatic market shift. Tapes are used under the bonnet, on the body and the interior and exterior trims of the car, where they offer various benefits over traditional joining technologies.

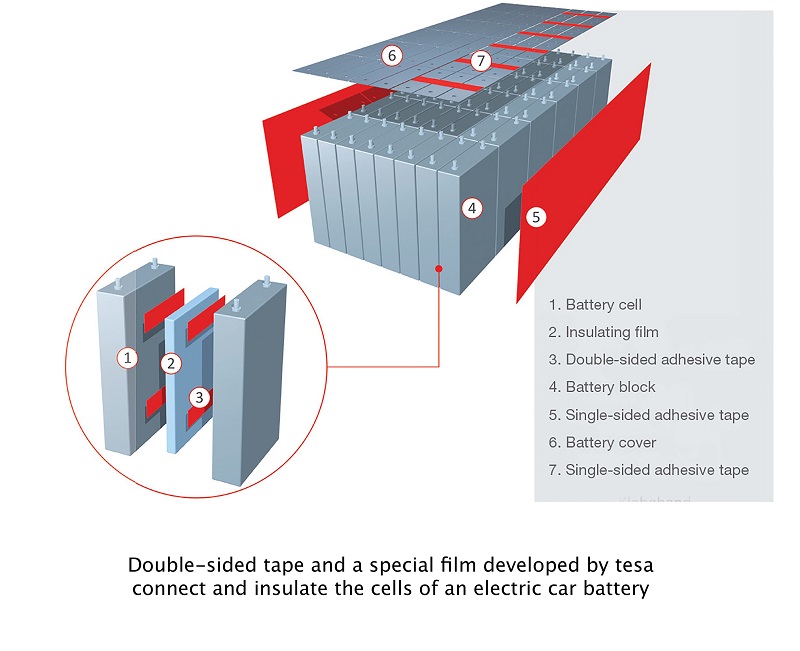

Adhesive tape is predicted to become a key component in the future of the automotive industry and not just because of volume demands. An electric car’s battery generates heat and voltage that needs to be shielded to ensure user safety, so tesa has produced a double-sided tape and special film that ensures no power surges can occur, with batteries having the ability to be wrapped in non-flammable products withstanding temperatures of up to 150°C. With the continuing drive to keep vehicle weight to the minimum, adhesive tapes offer an advantage over traditional mechanical fixings.

What’s more, tesa believes the reduced costs of adopting adhesive tape appeals to manufacturers as it is easy to be applied automatically and eliminates the need for welding. The process enables flexing and easily bonds dissimilar substrates, such as metal and plastic, with an aesthetically pleasing finished product - lumps and bumps caused by screws and bolts could soon be a thing of the past.

Wire harnessing is already widespread in hybrid vehicles and tesa already produces tapes offering an excellent bond that is resistant to both heat and abrasion. Vehicle weight is another integral part of the move to electric, with light weighting having a significant effect on fuel economy, sustainability and the realisation of better processing efficiencies and improved overall performance. Richard Powell from tesa’s Automotive Technical Sales Team comments:

“We have decades of expertise in both the automotive and electronics industries. With our technologically advanced adhesive tapes, including electrically conductive tapes (ECT’s), optically clear adhesive tapes (OCAs), and barrier tapes for applications in curved displays, we are in an excellent position for the future of automotive manufacturing”.

With products that offer bonding, encapsulating and fixing solutions along with aesthetic and noise dampening properties, tesa assures the manufacturing industry that it’s in safe hands as the move to electric vehicles continues to gather pace.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.