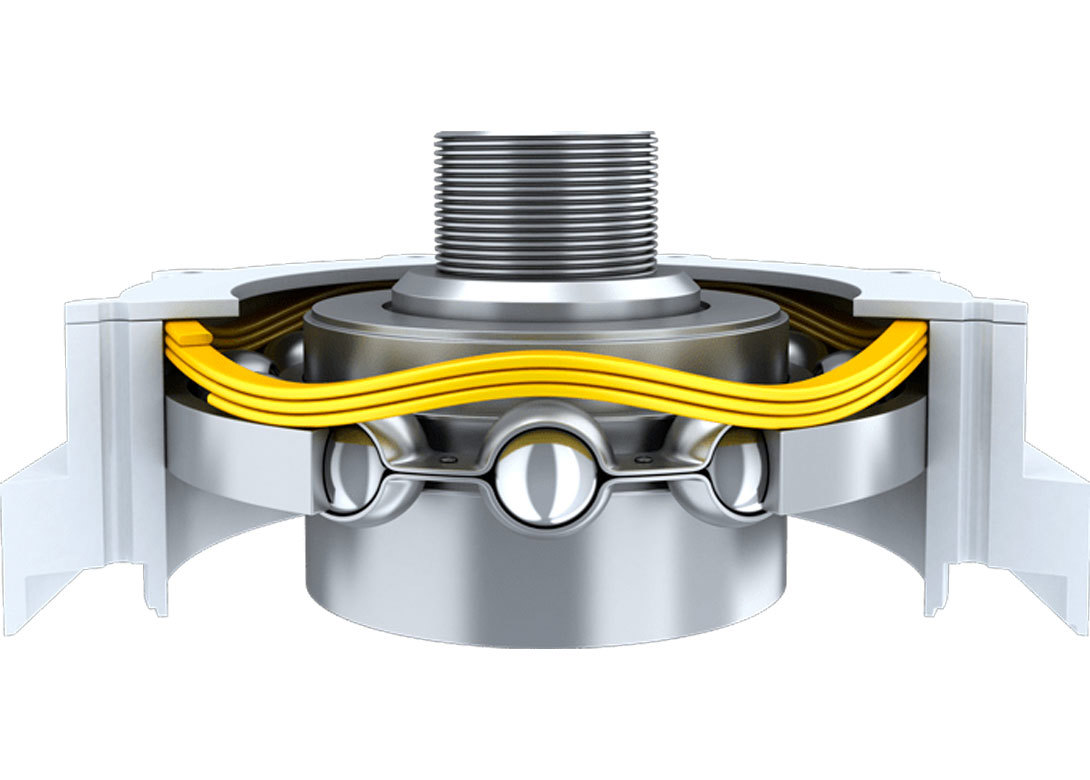

When assembling individual bearing components, the outer race, inner race, balls, and retainer all work together so that there is a controlled amount of internal clearance between the rings and balls. This radial play is necessary for proper operation, however, in most applications, it is also necessary to help reduce or eliminate the internal clearance to maintain correct functionality.

To remove this internal clearance, an axial load can be placed on a bearing race independently of the external load placed on it. This is called preloading, and it ensures constant contact - reducing or eliminating any play that may occur between components. This becomes a critical factor in most high precision and high speed applications.

There are two types of bearing preload: fixed and spring. In fixed bearing preload, the position of the inner and outer races of each bearing is mechanically fixed using either a dead weight (adhesive based) or through building in an axial adjustment that puts pressure on the bearings. Spring loading provides a constant load that can accommodate slight misalignments and is less expensive than fixed preloading.

Why is it important?

Benefits of preloading a bearing include:

- Extends bearing lifespan

- Elimination of ball skidding

- Vibration reduction

- Noise reduction

- Precise shaft positioning

- Greater load sharing between bearings

- Rotational accuracy

- Control and reduction of axial and radial deflection under applied load

Why use a wave spring for bearing preload?

A wave spring can provide all the benefits of spring preloading while also taking up dimensional variation from thermal expansion or cyclic loading. TFC offers many types of wave springs for the enormous range of applications across many industries.

Every application is unique, which makes selecting the proper wave spring very important. TFC has a standard bearing preload wave spring series (SSB), designed for popular bearing sizes. It should be noted that overall tolerances will be a very important factor as placing too much preload on the bearing can reduce longevity, while too little can cause higher noise output in high vibration systems.

Correct material selection will also be vital, as the incorrect material choice can lead to failure in operation. While wave springs are stocked in both Carbon Steel and 17-7 Stainless Steel, TFC is able to offer wave springs in a variety of alloys to meet an application’s operating conditions.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.