Cobalt has previously been widely used in conversion coatings as it’s a key contributor to heat resistance and corrosion protection. With a steadily increasing cobalt price, industries are calling for a cobalt-free alternative without sacrificing performance.

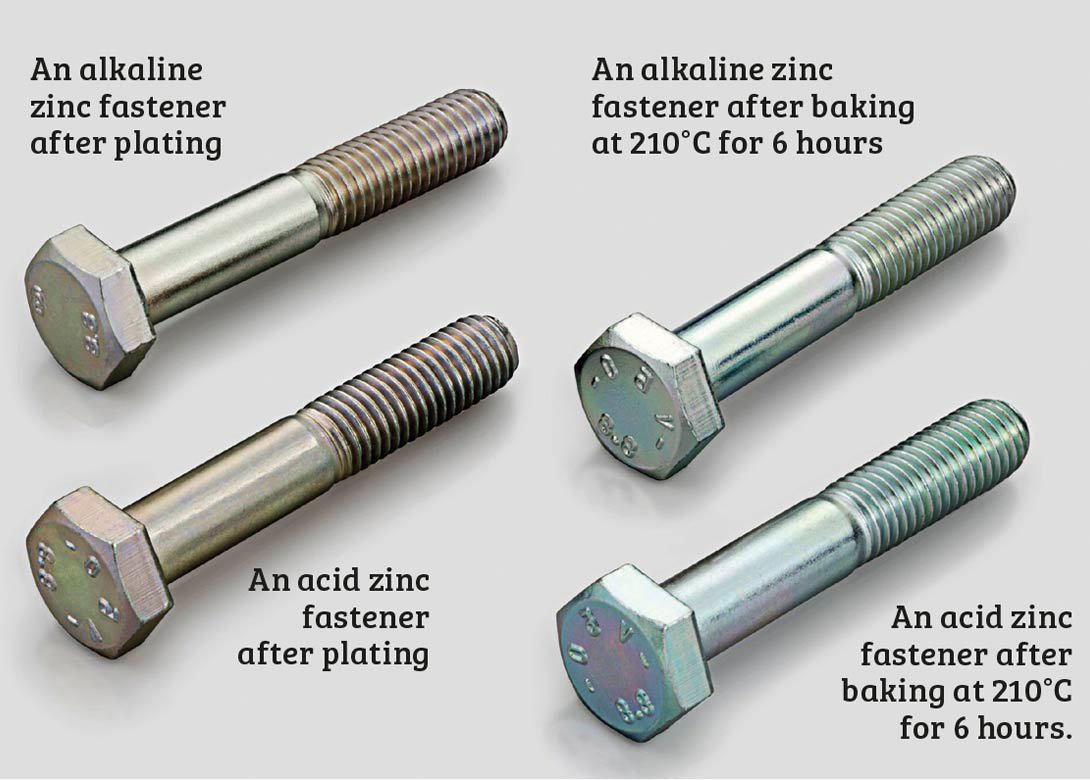

EcoTri® NoCo 2.0 is Atotech’s new high performance Cr(III)-based iridescent passivate for alkaline and acid zinc, completely cobalt and fluoride-free. The newest generation offers an innovative feature that is unique to cobalt-free passivates – the ability to withstand hydrogen de-embrittlement baking even after passivation. After baking at 210°C for 6 – 8 hours, EcoTri NoCo 2.0 exhibits no significant changes in appearance or evidence of corrosion. It shows excellent colour stability even after baking. 96 hours – 120 hours against white corrosion in barrel application and 120 hours – 168 hours in rack application are proven after baking.

The chemical reaction of Cr(III)-based passivates – also referred to as conversion coatings – releases a precipitation of Cr(OH)3 and the acidic attack of the zinc surfaces. EcoTri NoCo 2.0 shows reduced attack to zinc surfaces and consumption of additives, which consequently increase the lifetime of the passivate.

“EcoTri NoCo 2.0 makes us very proud,” explains Markus Ahr, global product manager for corrosion resistant coatings at Atotech. “It manifests our innovative strength and also our insistence towards achieving previously unattainable results: A cobalt-free thick film passivate for zinc offering the same high performance as cobalt, containing passivates, truly is a milestone. It helps our customers reduce the environmental footprint and save costs.”

For many years, Atotech’s brand EcoTri has stood for excellent corrosion protection and reliability. Products from the EcoTri range are widely recognised and approved by the automotive industry. In line with Atotech’s strategy to provide sustainable plating solutions, new generations of EcoTri products offer simplified wastewater treatment and economic operation at ambient temperature without compromising performance.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.