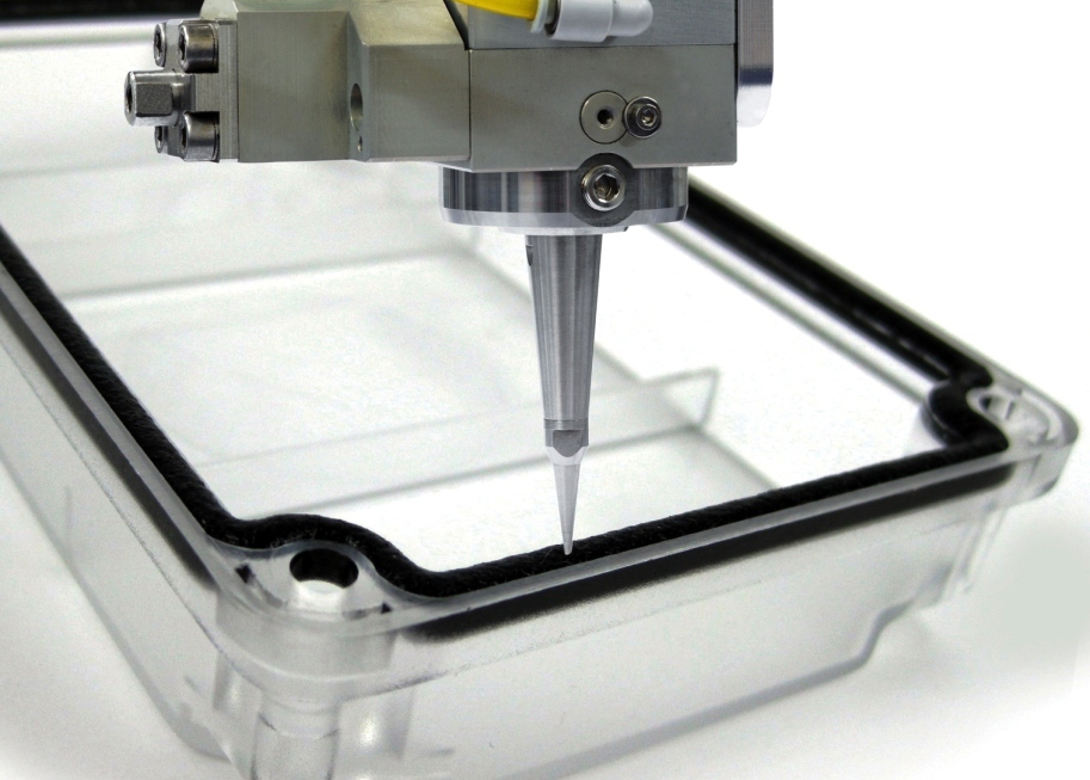

Techsil has launched a new leading edge PUR Form-in-Place-Foam-Gasketing service. Using an innovative single-component liquid-polyurethane-foam sealing system and machine technology, Techsil’s FIPFG service offers a solution for replacing labour intensive peel and stick gasket applications.

Taking measured quantities of material and compressed air the mixture is homogenised and, through sheer force, converted to a uniform foam structure upon application to the component. The curing process takes place without any chemical reaction forming a fine, closed-cell structure. The automated system can vary the ratio of material to air and create a wide range of foam hardness depending on the customer’s specification.

Technical sales manager, Steve Green comments: “Offering a contract gasketing service is a new venture for Techsil that has come about through customer need and dovetails nicely with our existing product portfolio. I can reveal that this service has particularly captured the interest of manufacturers in the lighting, electronics, automotive and packaging sectors.

Techsil’s contract gasketing service uses sophisticated six axis robot dispensing systems that provide the perfect bespoke gasket every time. Short cycle times save time and money. If a manufacturer produces small volumes or has intermittent production, then subcontracting their FIPFG system will be very cost effective.”

Techsil state that the dispensing of only one component ensures that even very small sealing gaskets can be produced accurately without any problems - from micro-dispensing of gaskets and replacement of o-rings, to high volume applications of foam to switch cabinet doors. The thixotropic properties of the foam ensure that tri-dimensional shapes and cross-sectional variations can be accommodated.

www.techsil.co.uk/foam-gasketing-service

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.