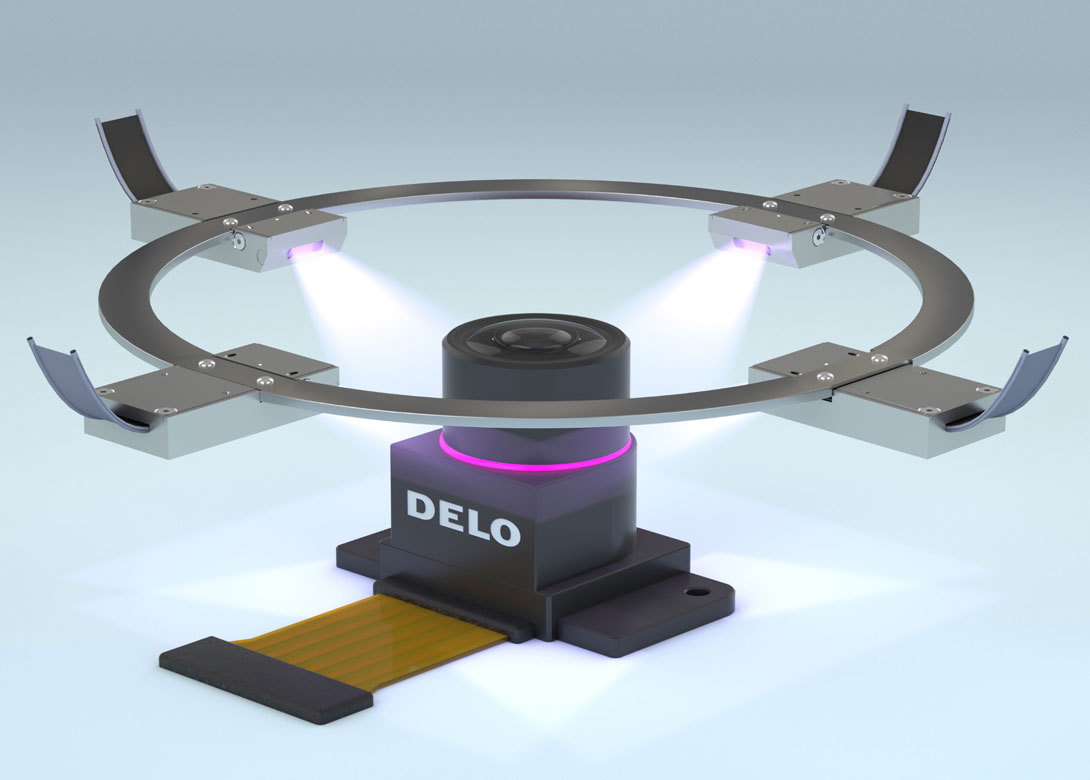

DELO has developed a particularly space saving UV lamp for adhesive curing. The powerful DELOLUX 503 is designed for industrial applications requiring small surfaces to be bonded within seconds in serial production lines, for example for bonding cameras used in autonomous cars.

Increasing miniaturisation calls for more compact production systems. When developing the new lamp, special attention was also paid to minimum installation dimensions. The lamp comes with another feature: its light is directed diagonally downwards, so it does not need to be installed at level with the components to be bonded. This gives more moving space to axes or grippers and facilitates integration into complex systems.

At a typical working distance of 15mm, the DELOLUX 503 curing lamp irradiates an area of 18mm x 6mm. This high performance spotlight source is available in two versions. One model, featuring a wavelength of 365Nm and a nominal intensity of more than 1,000mW/cm², has been optimized for fast fixation in less than a second. The second version with a wavelength of 400Nm and an intensity of more than 1,600mW/cm² has been developed with a focus on optimised deep curing of the adhesive and better penetration of hardly translucent plastics.

Thanks to continuous intensity control as well as internal control and monitoring of important parameters such as the LED temperature, the UV lamp ensures high process reliability. Up to four LED heads can be controlled by the DELO-UNIPRO and DELO-UNIPRO Light controllers or by an external PLC, allowing the adhesive to be evenly exposed from several sides.

LED lamps are the leading technology in the field of curing lamps. Their emission spectrum can be adjusted to the specific adhesive, enabling optimised curing of the adhesive and preventing unnecessary heat input into the component from unused wavelengths. The LEDs great longevity and low energy consumption help make production processes highly cost-efficient.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.