The structural strength of any door is dependent upon how strong the material is, whether the door gear is specified correctly and ultimately how strong the fasteners are themselves.

Available from Star Fasteners, the Hucktainer® fastener consistently provides proven joint strength, vibration resistance and overall durability. It has been uniquely engineered for use in structures fabricated from fibreglass reinforced plywood, metal-clad polymer core panels and other reinforced panel structures. Because Hucktainer has been designed to distribute force over a wide area, it will not crush, craze or bull-nose composite panels.

Used in conjunction, Star Fasteners has specifically designed restrictor shim - the fastener can be installed into lightweight composite materials (sandwich panel) without damaging the surface material.

In addition to high strength and vibration resistance, Huck® fasteners are maintenance free. There is no retorquing or retightening needed as with traditional nuts and bolts. This establishes Hucktainer as a superior value fastener; its lower maintenance requirements are reflected in negligible associated on costs. Huck fasteners deliver a better life cycle value through reduced warranty claims and longer life.

Hucktainer’s fool proof installation ensures that fasteners are installed in seconds. The two piece Hucktainer fastener has been proven to be reliable and vibration resistant in many applications and are also used in the assembly of side panels and bulkheads.

Star Fasteners in-house powder coating facility regularly powder coats Hucktainer’s to match customers livery. Polyester powder coating adds durability and provides additional corrosion resistance. By using high-quality powder, the process ensures a maintenance free, hardwearing finish which is also resistant to yellowing and fading over time.

The underhead seal protects the application from weather and contaminant ingress. The liquid applied seal is a unique resin matrix sealing product for under head encapsulation and works by compression seating. The material absorbs shock, movement and temperature differentials of thermal expansion between parts.

The growing trend towards lightweighting, the increased use of composite panel and also technological improvements in the commercial vehicle market has seen innovation in design. With this in mind Star Fasteners has brought to the market a coloured encapsulated Hucktainer.

Custom colour encapsulated head

- Colour matched to any colour of your choice.

- Low minimum order quantity and fast turnaround.

- Plastic encapsulated, UV resistant head reduces corrosion.

- Integral seal prevents weather ingress.

- Increased head diameter spreads the load; helps eliminate panel crushing.

- Neat appearance gives a professional finish and blends seamlessly with the livery colour.

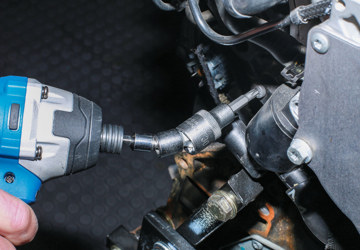

Unlike impact wrenches, the tools used to install Hucktainer fasteners are quiet and come in a choice of battery powered, air-powered of hydraulic models. Star Fasteners have a choice of quality battery powered installation tools capable of enduring tough environments. They are proving to be a popular choice with service teams and assembly lines and are an invaluable tool for working in areas where there isn’t any power on site. Battery tools are becoming the ‘go-to’ tool; they are generally lighter to use which allows for ease of movement as they can be manipulated into confined spaces and there is no airline to get tangled or trip hazards.

Hucktainer® benefits

- Fast, quiet, fool proof installation

- Installs with consistent pressure, reducing crushing or crazing

- Spiral lock system, breakaway pintail, and smooth bore sleeve

- Exclusively from Star Fasteners;improved zinc nickel J63 plating resists corrosion (offers 720 hours without ferrous corrosion)

- Integral seal keeps contaminants from invading joint / weather-resistant

- Eliminates the requirement of torque settings

- Tamper-resistant

- Custom colouring for encapsulations available, with short lead times and low order quantity

- Shorter grips available for today’s thin metal-clad panels

- RoHS (Restriction of Hazardous Substances) compliant

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.