Building on years of experience and expertise in engine and powertrain applications, Henkel is actively investing in new technologies and products for efficient large-scale manufacturing of safe and reliable electric drive systems. Key solutions addressing the “pain points” of OEMs and tier suppliers in this segment include innovative liquid gasketing, magnet bonding, thermal management and potting products as well as a state of the art impregnation service.

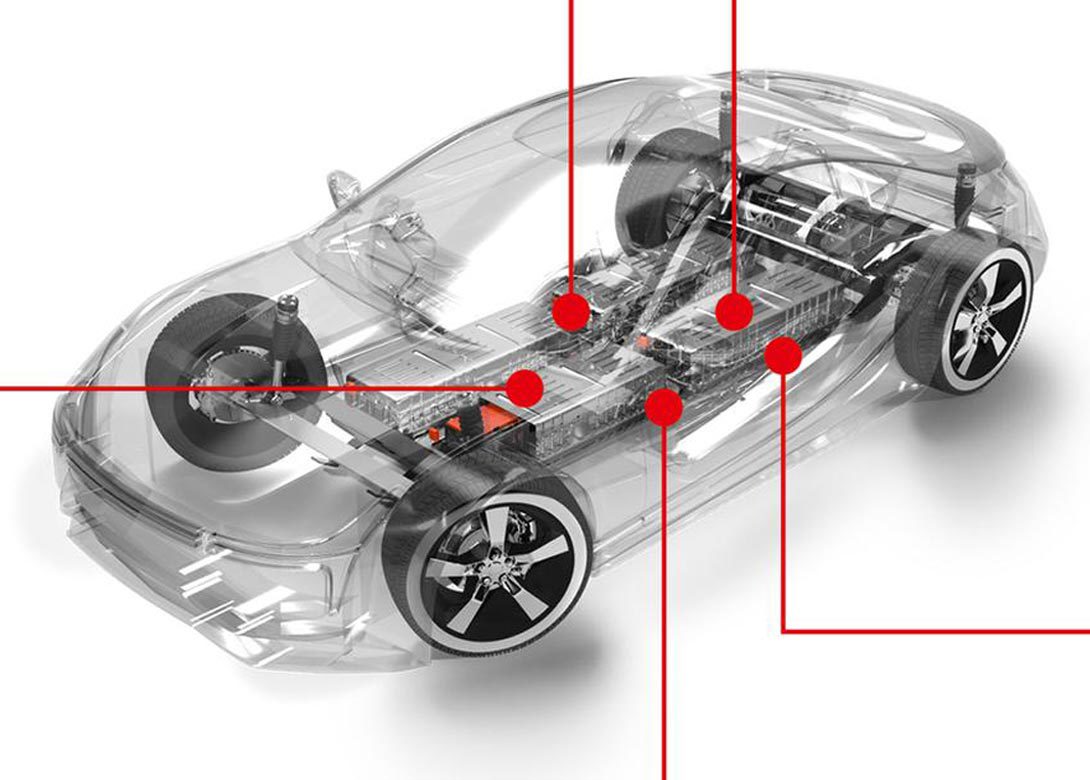

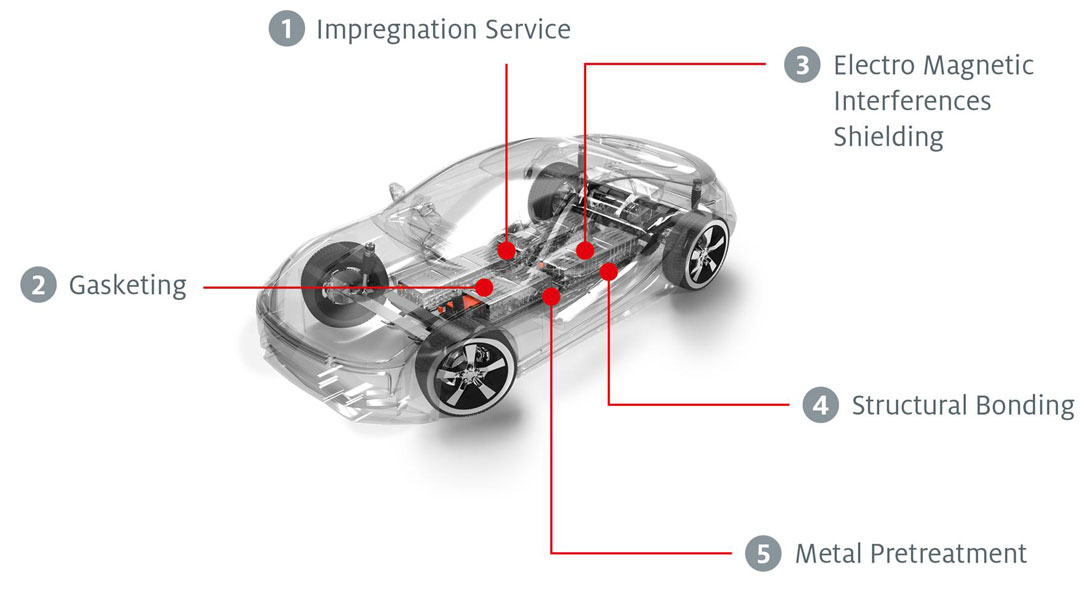

Electric, digital and autonomous – the automotive industry is facing disruptive changes, where advanced battery technology and electronics are going to reshape the design and manufacture of vehicles. Henkel is determined to play a decisive role in this transformation, helping customers drive the future of e-Mobility and benefit from the company’s comprehensive product and service portfolio for efficient, reliable, safe and sustainable solutions across the entire manufacturing chain of components.

Next to liquid sealants, thermal interface materials, adhesives and impregnation resins for new-generation battery packs, Henkel is leveraging existing and new products and technologies for the emerging trend towards e-drive modules combining electric motor, power electronics and gearbox in one integrated e-axle unit. In addition, customers are also supported with appropriate design guidelines and recommendations for process requirements including equipment enabling automated high-volume production.

“The electrification of vehicles is gaining pace and helps automakers reduce their fleet fuel consumption and CO2 emission footprint in line with strict regulation targets,” says Frank Kerstan, global business development, powertrain and e-mobility at Henkel.

“As all major OEMs and new players in the automotive industry are launching more and more full hybrid and battery electric vehicles there is a need for seamlessly matching technologies designed to support these new drive concepts and manufacturing schemes. With our innovative adhesive solutions, we are ideally positioned as a full-service partner of customers at the forefront of e-Mobility,” comments Frank.

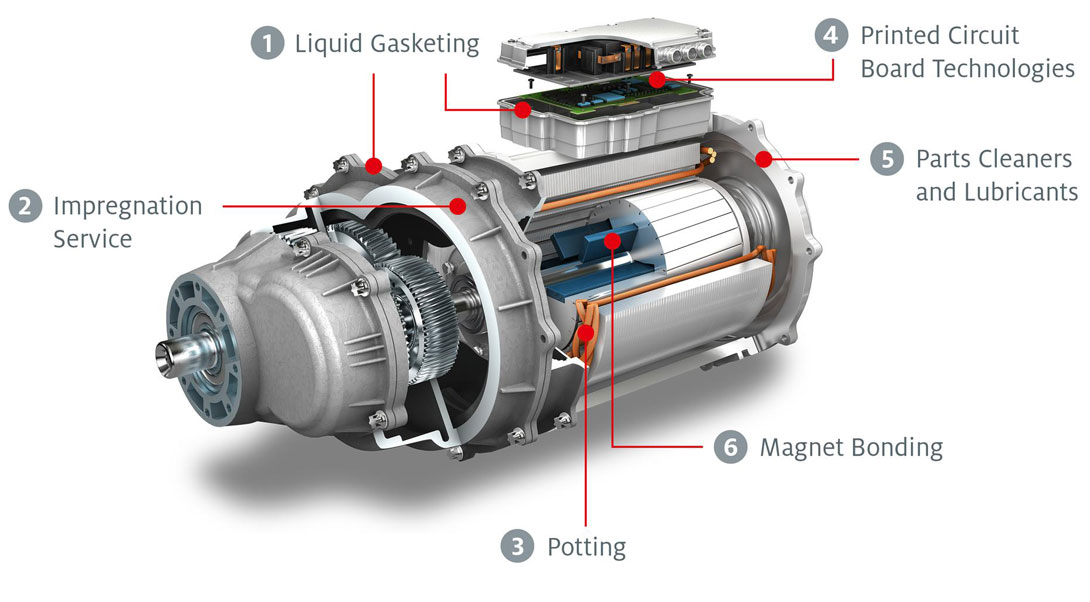

Henkel’s portfolio of efficient, safe and sustainable solutions for the entire value chain of e-drives manufacturing is focused on six key application areas:

Liquid gasketing: Henkel offers a wide range of different gasketing technologies. Latest product innovations include Loctite AA 5820, which is especially suitable to provide a reliable seal of multi-substrates or any flange design of e-drive housings. The polyacrylate adhesive shows excellent resistance to oils, including automatic transmission fluids (ATF), and can withstand temperatures from -40°C to +150°C

Potting: Another polyacrylate technology – Loctite AA 5831 – is used for protection and fixation of parts in the e-motor or in the conversion electronic control unit. The compound has an ideal fit in large-series potting operations and cures within seconds under UV light and moisture. For e-drive stator coil potting applications, Henkel offers the two-component epoxy technology of Loctite PE 8082 which has a thermal conductivity of 1 W/mK, resulting in a significantly reduced working temperature. In addition, it shows outstanding oil resistance.

PCB technologies: Printed circuit board solutions include conformal coatings, thermal interface materials, low pressure moulding products, and next generation of solder technologies for e-drive power conversion control units.

Impregnation service: Henkel’s Loctite Impregnation Solutions (LIS) service leverages the flowability of low-viscosity polymeric resin to fill micro-porosities and voids (“leakers”) and permanently seal components, such as aluminium cast e-drive housings, against common automotive fluids. The company operates 30 LIS Service Centres worldwide, which are fully certified to IATF 16949, ISO 14001 and OHSAS 18001.

Magnet bonding: Loctite EA 9497 is used for the bonding of magnets inside the e-motor. The two-component epoxy adhesive has proven its long-term reliability in this application segment, combining a wide operating temperature range of -55°C to +200°C with high mechanical strength as well as good chemical and oil resistance. With its added thermal conductivity, it also supports a more efficient thermal management.

Parts cleaners and lubricants: Henkel’s range of machining products along with parts cleaners help to maintain a cleaner part through the entire process to ensure tight tolerances and reduce residues on parts, especially when used on sensitive e-drive modules

Henkel has a well established reputation for its flexible capability of developing and tailoring specialised solutions to customer specifications. This is backed by technical test centres around the world and a strong focus on R&D and innovation. In addition, the company also maintains an extensive partner network for equipment, tools and engineering to serve a global OEM and tier 1 customer base. The complete line of Henkel’s adhesive solutions for the design and large-series production of next generation automotive electrical drive systems underscores the company’s commitment to anticipate the needs its customers for electrification.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.