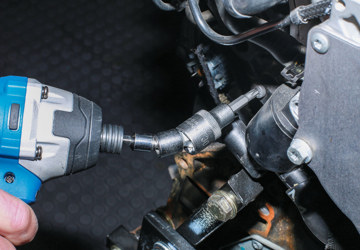

Techsil currently supplies a wide range of tapes into the automotive market to satisfy the ever changing requirements of this market. Designers are looking to remove mechanical fasteners such as rivets and screws and replace them with lighter, dependable engineered bonding solutions.

To help automotive customers deliver brand consistency and enhance the value of their products, Techsil has developed a range of easily applied adhesive tape solutions used to affix exterior badges, emblems, nameplates, trims and decorative embellishments in place.

These tapes meet even the most demanding material attachment and mounting requirements and can be used with a wide variety of OEM paint systems and substrates, including painted surfaces, ABS, polypropylene, stainless steel, aluminium and chromed metals.

- Double sided acrylic foam tapes - these viscoelastic foamed adhesive tapes offer semi structural bond strength, high adhesion and good shear on a variety of OEM paint systems and substrates. Effective on automotive exterior badge, emblem, logos and trim assembly applications.

- Double sided clear PET tapes - designed for exterior applications, these repositionable, densely cross-linked pure acrylic adhesive tapes resist extreme weather conditions and display excellent gas immersion resistance. They can be used for mounting ABS and rubber parts and can be die-cut to suit specific applications.

- Protective removable tapes - Techsil’s customers are producing high quality, high value parts which need protection, either during the production process or post production in shipping. These single sided filmic protection tapes offer high peel strengths and are designed not to leave any residue on removal chromed badge and emblem substrates, even after long term use.

- Adhesive tapes for electric vehicle batteries - there is no denying that electrical and hybrid vehicles (EV) are growing in popularity, being cheap to run, quiet and smooth to drive. Automotive manufacturers are keen to improve the power to weight ratio by using lighter materials such as composites and weight saving bonding, joining and fixing solutions.

Double sided tape and single sided self adhesive tapes offer an attractive alternative to traditional mechanical fastening methods and have a key role to play in the manufacture of electric cars, vans and public vehicles. From structural bonding tapes and anti-noise tapes to prevent rattles and squeaks through to closed cell foam tapes to provide waterproof seals there are many options.

Techsil offers a specialist adhesive tapes range designed specifically for lithium-ion automotive battery applications that meets the stringent requirements of the EV industry. This range of electrical tapes offers properties such as EMI shielding, Thermal & Electrical Insulation, Flame Retarding and Heat Sink Optimisation. The range is manufactured by ITW Stokis Tapes and includes:

- StokTherm - thermally conductive interface tapes that can give electrical insulation or act as a thermal pad cooling bridge to the cooling unit.

- ITW Formex - a range of tapes that offer mechanical protection, electrical insulation and EMI shielding to battery covers and busbars and can be used as a battery cell separator.

- StokSeal - a range of PU and silicone adhesive foam pads that are used for cushioning, thermal insulation, sealing of housings and connectors against water ingress and as compression pads giving compensation for cell expansion.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.