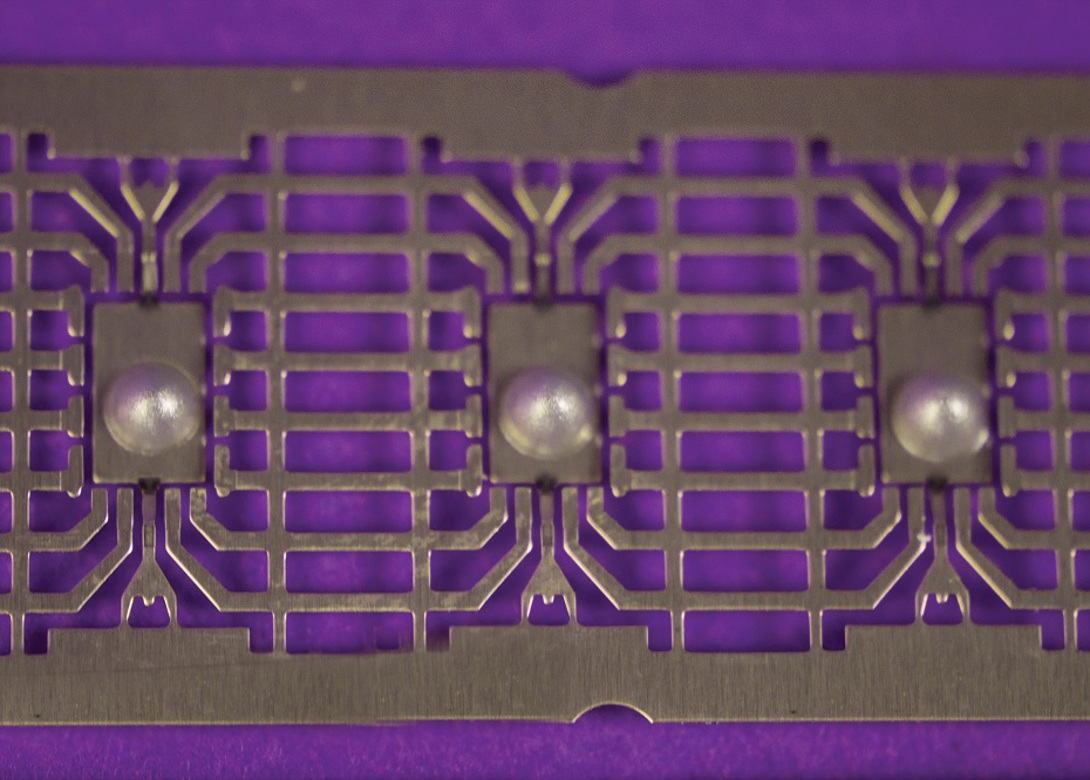

Master Bond EP3HTSDA-1 is a single part, no-mix epoxy adhesive designed primarily for die attach applications. It exhibits a die shear strength of 20 - 22kg-f and has a high thermal conductivity of over 40 - 45BTU•in/ft2•hr•°F [5.7 - 6.5W/(m•K)]. “This 100% solids formulation has an ideal viscosity and flow for die attach, will not ‘tail’ and can be easily dispensed automatically” says Rohit Ramnath, senior product engineer. “Additionally, it has an unlimited working life at room temperature and will cure in 20 - 30 minutes at 250°F or 5 - 10 minutes at 300°F.”

Master Bond EP3HTSDA-1 is NASA low outgassing approved. Dimensionally stable, it has a Shore D hardness of 75 - 85 and is engineered to withstand thermal cycling and shock. This epoxy system adheres well to metals, ceramics, and silicon dies, with a service operating temperature range from -80°F to +400°F.

The adhesive contains silver fillers and has a volume resistivity of <0.001ohm-cm. It retains conductivity upon aging and provides excellent moisture and chemical resistance. Formulated for applications in the communication, aerospace, medical, electronic, automotive, and defense industries, Master Bond EP3HTSDA-1 is available for use in syringe applicators.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.