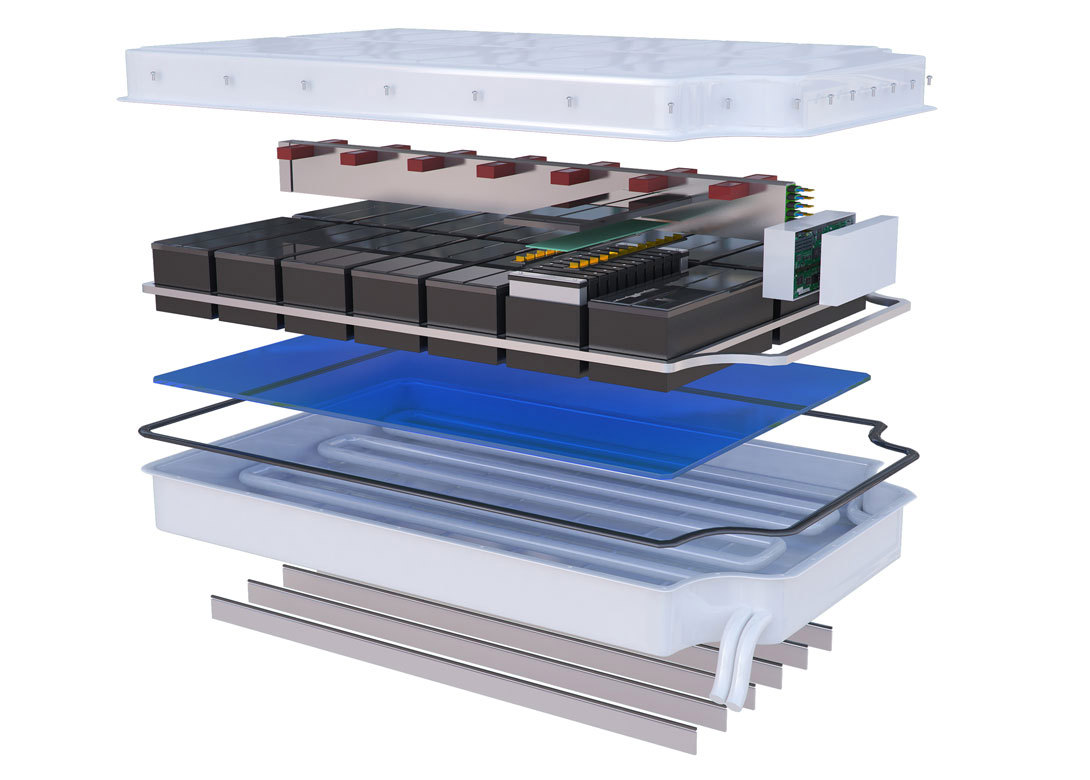

Dow, a global leader in silicones, silicon-based technology and innovation, has launched the DOWSIL™ EA-4700 CV adhesive, a next generation silicone solution for transportation assembly that is capable of room temperature curing at faster speeds while maintaining the performance advantages expected from silicone adhesives.

This advanced new assembly solution bonds at room temperature to traditional metals and plastics used in electronics assembly. DOWSIL™ EA-4700 CV Adhesive also offers low levels of volatile condensable materials to support its use near sensitive electronic components.

“Electric vehicle and autonomous vehicle development is accelerating across the industry, and engineers globally are seeking innovative solutions to meet safety and reliability requirements while achieving more efficient throughput to produce battery packs and ADAS sensor modules such as RADAR, LiDAR and cameras. DOWSIL™ EA-4700 CV Adhesive provides durable adhesion and environmental sealing of substrates used in automotive electronic modules, including aluminium, PBT and PPS. Importantly, this silicone adhesive’s ability to provide faster curing at room temperature enables increased throughput for efficient mass production with less use of energy,” said Bruce Hilman, global segment leader for transportation assembly at Dow Performance Silicones.

With room temperature (25°C) curing, this new adhesive achieves 1 Megapascal (MPa) adhesion strength within three hours, depending on the substrate material. Using new chemistry and formulation techniques, faster cure times are achieved with reasonable open time and dispensing. Both factors are important to assembly process efficiency. By reducing or eliminating oven curing, manufacturers can reduce capital expense and energy usage during operation.

The technology used also allows heat exposure to accelerate adhesion development, without the risk of voiding. For example, exposure to heat at 80°C, a temperature compatible with most plastic substrates, for less than 5 minutes allows 1 MPa of adhesion to build on polybutylene terephthate (PBT).

The two part, primerless adhesive, cures rapidly after mixing and provides stable adhesion and sealing performance under a typical operational environment of 150°C, thermal shock, and 85°C/85% relative humidity. This advanced assembly solution also has 600% elongation, which makes it suitable for larger modules that experience a coefficient of thermal expansion (CTE) mismatch between substrates.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.