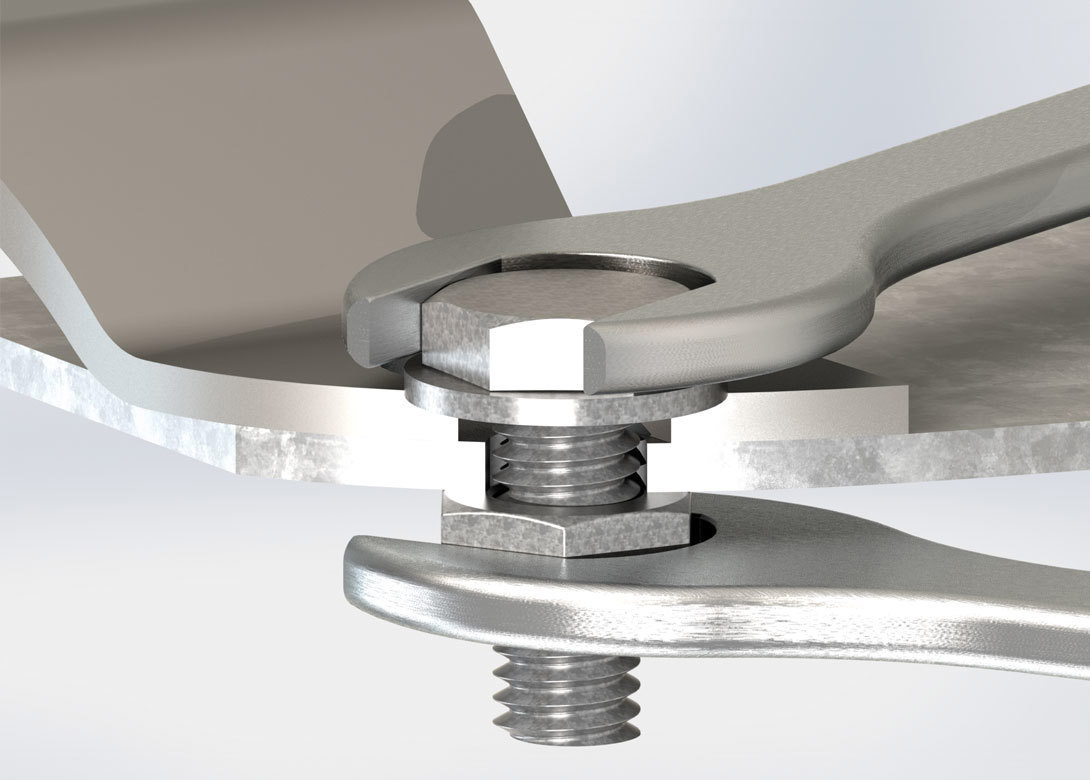

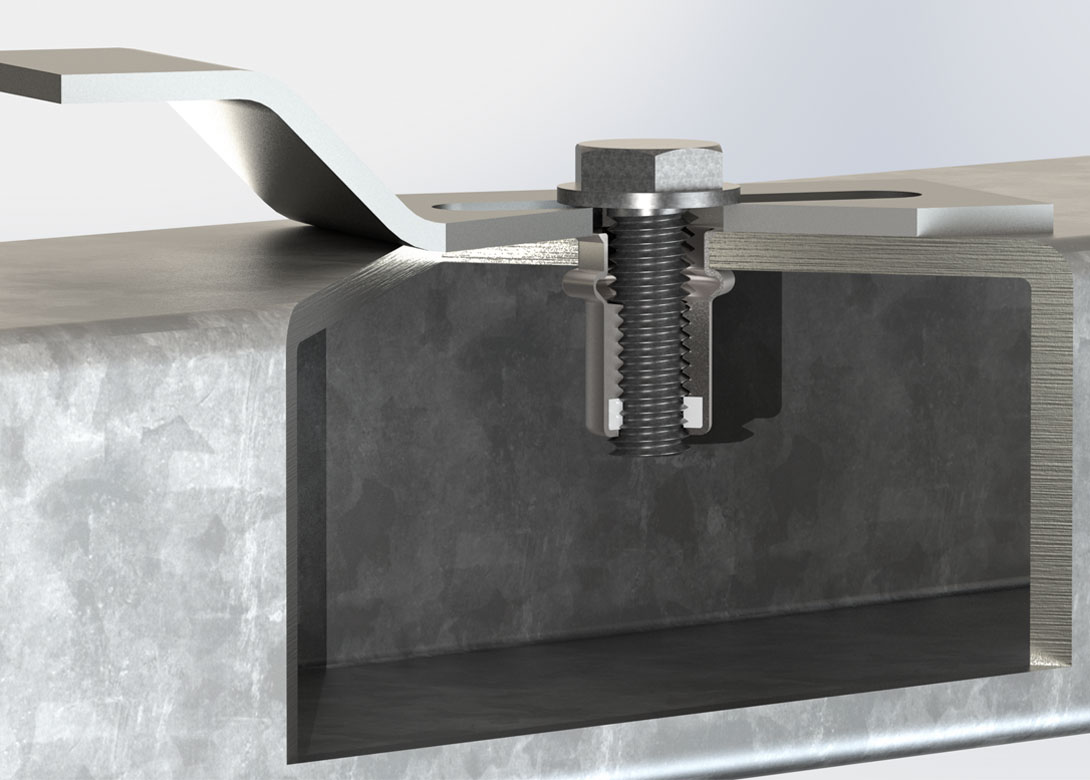

In high vibration applications bolts can become unscrewed from the rivet nut – this is why Specialinsert has developed the threaded Deform-Nut self-locking deformation insert. Designed, patented and produced to combine the advantages of the classic deformation rivet with the function of self-locking nuts.

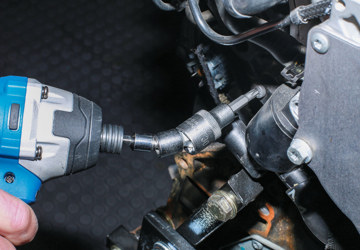

Ideal for many industrial applications from automotive to railway, from naval to furniture the threaded Deform-Nut self-locking deformation insert offers considerable technical advantages. These include installation on parts without the possibility of access from the inside; avoid the loosing of the mechanical fixing on the seat; quick assembly of the connection screw since, unlike the self-locking nut, it does not require the use of two tightening keys (double key), and the avoidance of the undesired unscrew of the bolt.

The parts are available with round or hexagonal bodies, with reduced or flat flange and made of stainless steel or zinc plated steel.

For the last 40 years Specialinsert has developed and produced fastener systems for every kind of application, through its International Sales department located in Turin headquarter, and is exporting today in 79 foreign nations. With the recently achieved certification IATF 1694 Specialinsert is a qualified partner for all the OEM and tier one in the automotive market.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.