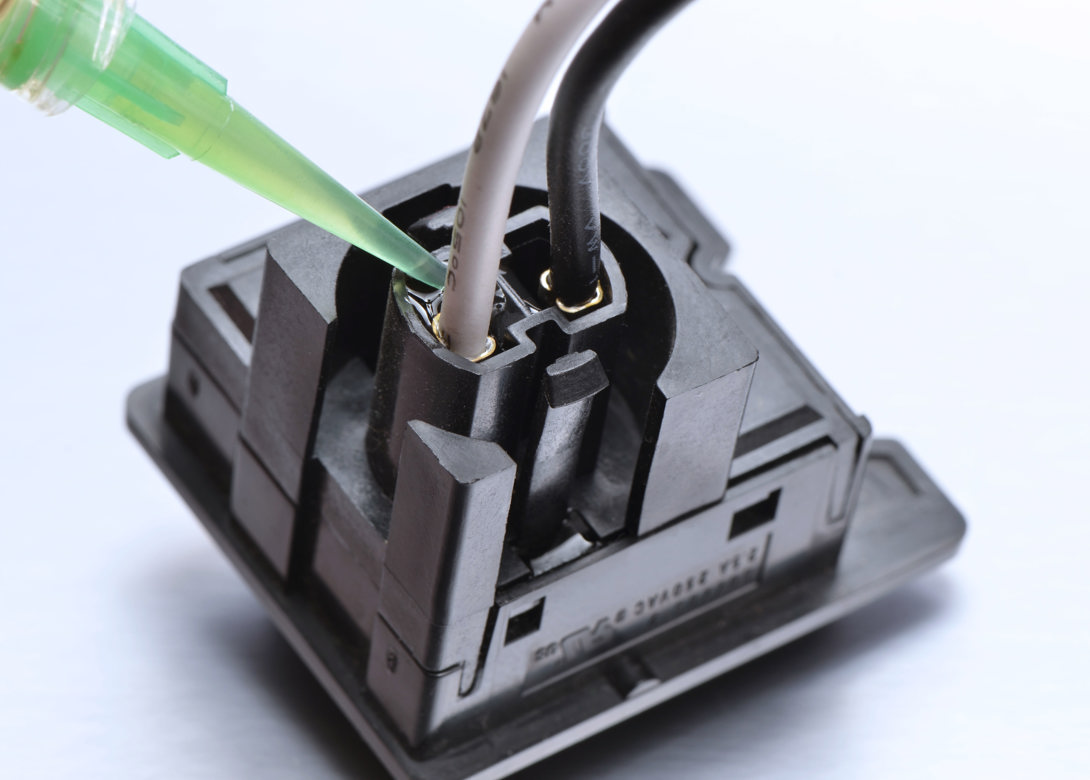

Master Bond EP21AC is a two part epoxy with a non-halogenated filler that is formulated for applications where arc resistance and flame retardancy are required.

Electrical arcing is a challenge for numerous electronic or electrical devices; this occurs when electricity jumps from one connection to another, resulting in an electrical breakdown. The air surrounding the current becomes ionized and arcs, which may lead to combustion and fire. EP21AC is designed primarily with the aim to prevent arcing related issues.

“EP21AC withstood over 150 arcs without igniting and therefore was assigned the highest PLC (Performance Level Category) of 0 under the UL746A High Amp Arc Ignition test,” says Rohit Ramnath, senior product engineer. “The compound is also flame retardant, as per the UL94HB standard for flammability testing. This combination of unique performance properties makes EP21AC suitable for encapsulating, potting or coating in many demanding applications.”

The system is toughened, with an elongation of 10% to 20%, and is capable of resisting thermo-mechanical stresses. It is an excellent electrical insulator with a volume resistivity greater than 1014 ohm-cm, and a dielectric constant of 4.7 at 75°F. Other noteworthy properties include a tensile strength of 5,000-6,000 psi, and a tensile modulus of 300,000 psi - 350,000 psi at 75°F. It is serviceable over the temperature range of -60°C to +90°C (-75°F to +194°F).

EP21AC has a convenient to use 1 to 1 mix ratio by weight and cures at room temperature, or more rapidly with heat. It has good flow properties with a mixed viscosity of 30,000 cps - 50,000 cps, and a relatively long working life of 75 - 120 minutes at room temperature. This compound bonds well to a variety of substrates including metals, ceramics, composites and many plastics and rubbers. It is available for use in ounce kits, ½ pint, pint, quart and gallon container kits. Specialty packaging is also available in premixed and frozen syringes.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.