Electronic components in computers and smartphones, or in household, entertainment and automobile technology, are indispensable in innovations relating to all areas of modern technology. Usually hidden from view beneath the product surface, extremely complex electronic systems must be designed, manufactured and launched onto the market in the shortest time possible at an acceptable price. They also need to be totally reliable and energy efficient products. Rapidly increasing capabilities and constant miniaturisation have characterised developments in electronics for decades.

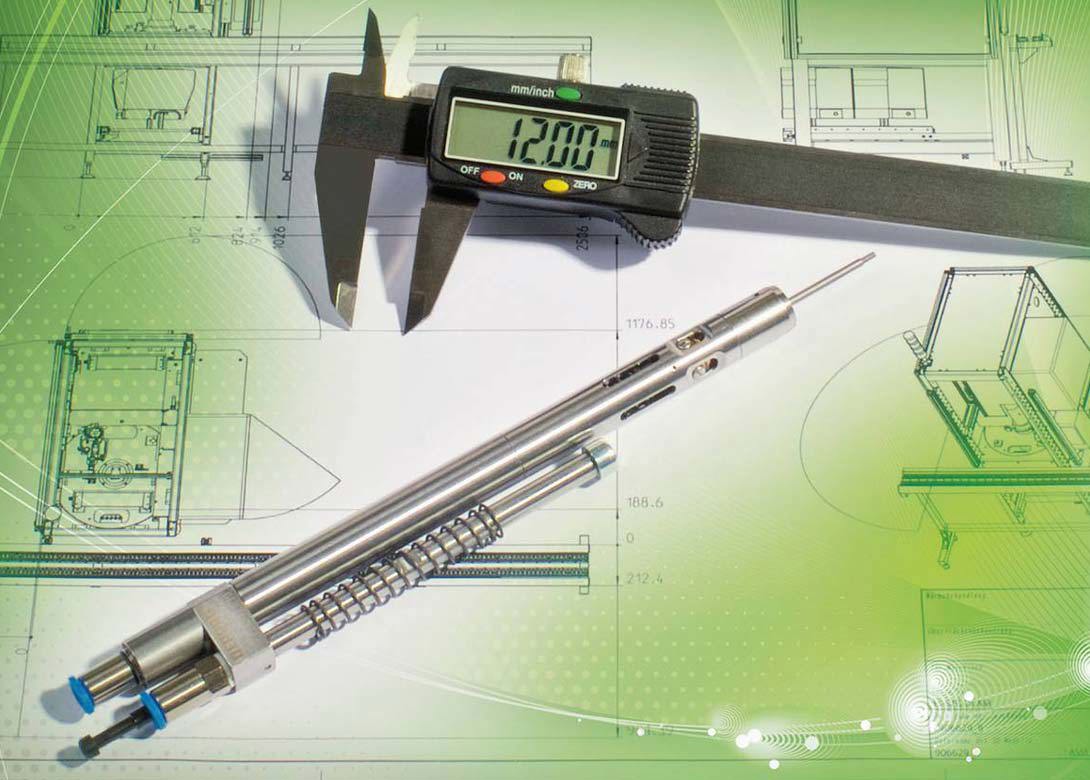

DEPRAG Schulz GmbH u. Co is known for continuous optimisation of its products and for leading the way with new developments in the assembly of miniature components. The screwdriving technology specialist has a specific screwdriver in its programme especially for intricate assemblies – the NANOMAT. This screwdriver reaches highly accurate, extremely low torques from 8Nmm to 300Nmm at speeds of up to 1,700 1/min – and that in four different speed ranges. DEPRAG says its NANOMAT screwdriver has one of the smallest torques on the market and is available both for manual and stationary assembly tasks.

The NANOMAT has a wide range of applications - whether in medical technology for the reliable processing of hearing aids or pacemakers, in the watch industry or precision engineering for the manufacture of measurement devices. Another application area is the assembly of objectives, cameras and microscopes in the optical industry, where tiny fasteners must be assembled. In the production of electronic products and components, such as smartphones, games consoles and computers, the miniaturisation of devices has a great influence on the type of assembly required.

A flexible EC screwdriver for the highest standards

The NANOMAT-EC spindle screwdriver provides the highest possible processing reliability for industrial assembly due to its reliable and low maintenance brushless EC motor. It is designed with excellent dynamics and top torques to be the ideal driver for screw tightening. It features integrated torque recording based on precise motor current measurement and the evaluation of additional dynamic influencing factors, as well as torque measurement enabling exact control of multi-stage screwdriving processes and the documentation of screwdriving results.

DEPRAG screwdrivers are based on EC technology and can boast a torque accuracy of < 2% standard deviation which remains true for millions of cycles. Therefore, the machine capability index of ≥ 1.67 at a tolerance of ±10% relating to 6 Sigma is attainable. A cmk value of 1.67 means that the error percentage is under 0.6 per million screw assemblies.

Maximum flexibility and processing reliability with the sequence controller AST6

The sequence controller AST6 is the ideal controller for stationary screw assemblies used with the tried and tested NANOMAT-EC screwdriver. It guarantees highest precision at low torques, is extremely user friendly and allows precise monitoring of angle and torque.

The sequence controller already contains standard screwdriving programs for assembly to torque and loosening to angle. Parameters can be adapted to the current screwdriving task via the touch screen and the AST6 enables free programming of screwdriving sequences.

The pneumatic screwdriver as a basic solution

The pneumatic NANOMAT is available as a handheld or spindle screwdriver for stationary use. The NANOMAT screwdriver realises high precision torque control due to the solid principle of the mechanical decoupler and shut-off clutch. This high-precision shut-off clutch enables torque accuracy of less the ±3 % standard deviation, even after millions of operating cycles. Under appropriate operating conditions the DEPRAG air driver with shut-off clutch attains a cmk value of ≥ 1.67 with a tolerance entry of ± 10 % relating to 6 Sigma in accordance with ISO 5393. Expressed a different way, a cmk value of ≥ 1.67 means an error percentage of only 0.6 per one million assemblies! The pneumatic screwdriver can quickly and simply be set to the required torque without the need for special tools.

Another advantage of the DEPRAG NANOMAT is the ergonomic handle enabling sensitive and precise screw handling. In addition, the integrated quick-change chuck allows fast, simple bit exchange without the need for tools. This means that standard bits with A3 connection in accordance with DIN ISO 1173 can be used. Vacuum suction via the integrated vacuum implement is also a plus point - eliminating any inconvenient hoses around the handle or screw.

The NANOMAT spindles can be easily integrated and are particularly small in size. Screwdrivers are available in right rotation, left rotation and reversible, with push-to-start or start via remote valve. The extremely slim-line design of the NANOMAT spindle screwdriver measures just 12 millimetres in diameter and is therefore perfect for small gaps between screw positions in stationary use.

Of course, the NANOMAT spindle screwdriver also benefits from the famous DEPRAG guidance system which regulates optimal pressure on the screw via spring tension.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.