Safety is an issue both in finished products and in the manufacturing process. Here, JET PRESS looks at a few ways to improve safety by using the right fastener:

Shake, rattle and roll

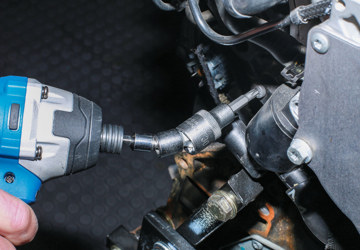

Movement and vibration in machinery and automotive situations causes problems for engineers. When components move, the fasteners holding them together can become loose and fall out. Engineers can tackle this problem with anti-vibration lock nuts and locking washers that stop nuts from loosening from vibration or dynamic load.

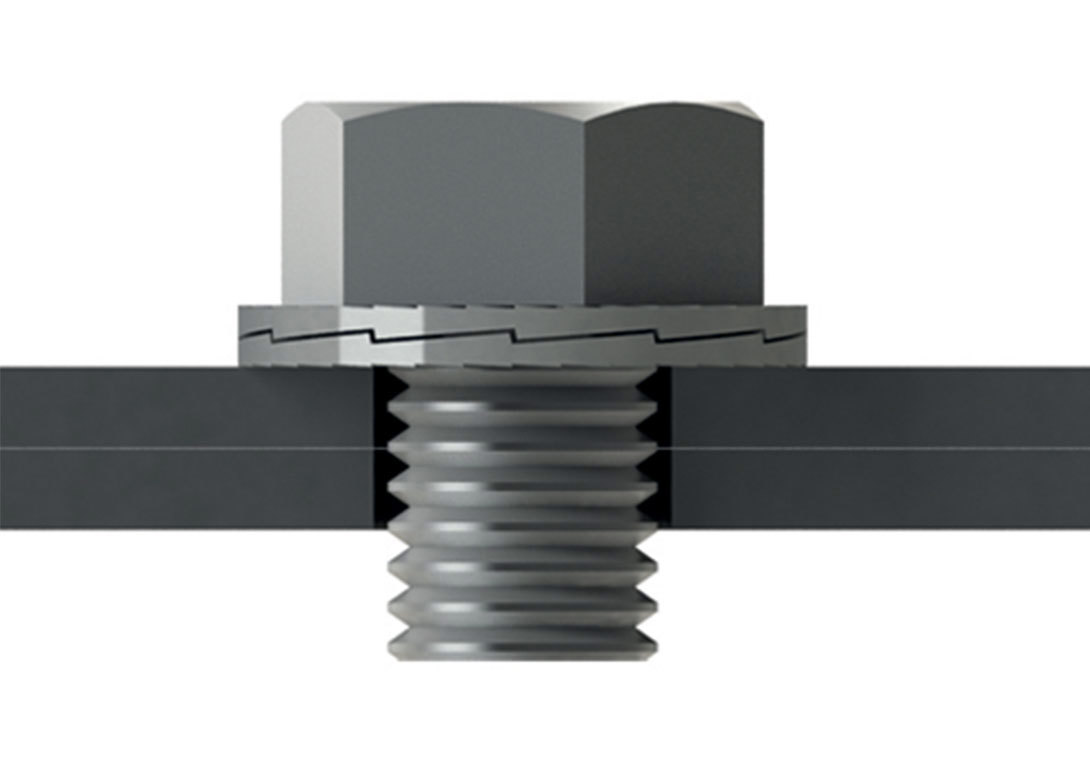

Palnut regular lock nuts are a popular and cost-effective solution. The unit cost is low and they’re quick and easy to use. Turn the lock nut to finger tight then use a spanner to tighten them a further third to half a turn - no need for a torque wrench. You can see the lock nut has been properly tightened because the hex face becomes slightly concave. The palnut works by pushing the teeth of the thread form down the thread helix until the ends of the teeth bite into the root of the thread on the bolt.

Nord-Lock washers are also an alternative to lock nuts and work in a different way, using tension rather than friction. Each washer comes as a pair and you use them with a conventional bolt. The outer surface has serrations that dig in to the lower surface of the bolt and the mating surface and the mating surfaces of the washers have cams. Because the angle of the cam is greater than the helix angle of the thread of the bolt a wedge effect is created when you tighten the bolt.

Anti-vibration solutions for all seasons

Nord-Lock washers have a high-level of corrosion resistance and you can specify palnut regular lock nuts with a hot dip galvanised finish that offers corrosion resistance up to 1,000 hours of salt spray. Lock nuts and locking washers are used in the assembly of electricity pylons, where of course safety is hugely important.

Do you have a nut loose?

Bolts that drop out of machinery can injure people and cause damage so they are a real safety risk. So how do you secure fasteners, especially ones that are frequently loosened and tightened?

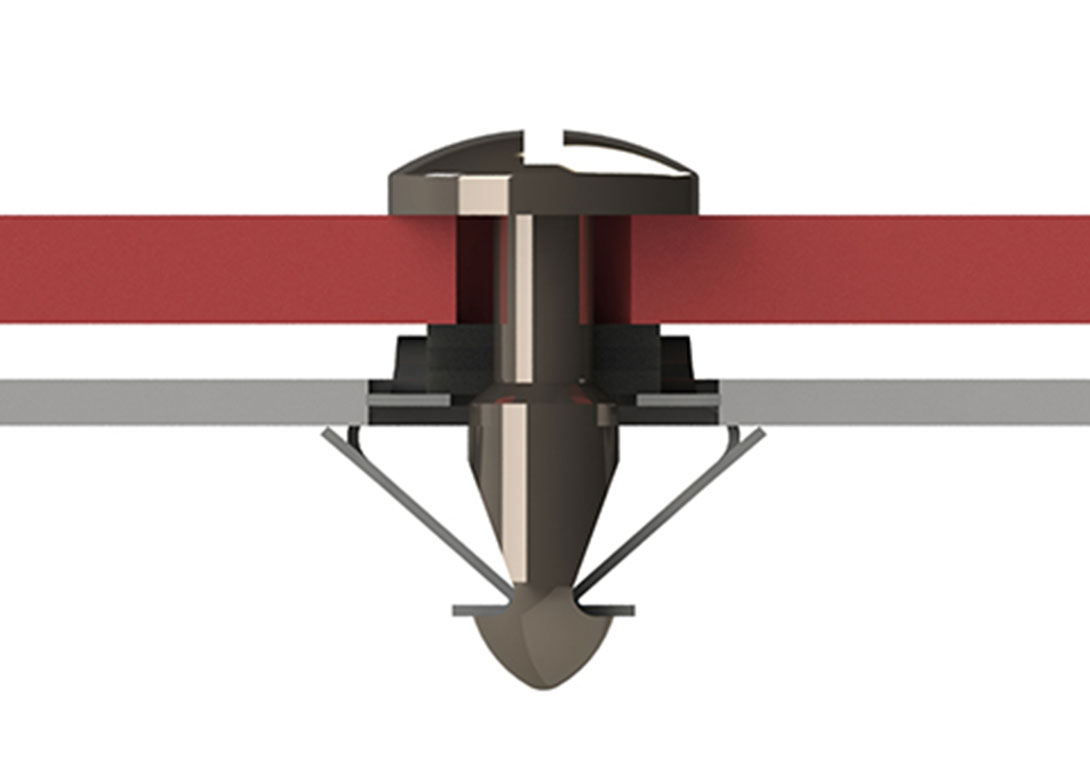

Designers working in situations from heavy industry to building campervans use bi-fix quarter turn fasteners. They’re useful anywhere that panels or doors need to be regularly opened or removed for maintenance. People like them because they’re easy to use and they can’t fall out of the panel and cause damage or injury.

The main types are quarter turn dome head studs, quarter turn wing head studs and quarter turn knurled head studs. You just turn them through a quarter turn to open or close them. A wing head stud can be released by hand, so can a knurled head stud. Both the knurled head stud and the dome head stud are slotted so it can be opened with a flat blade screwdriver.

A bi-fix quarter turn fastener is made up of 3 parts. The spring clip which is installed permanently in the framework. It’s the spring that ejects the stud. The stud stays captive in the panel which is being removed by means of a washer. The washer also reduces vibration when everything is in the assembled or closed position.

Push nut bolt retainers can also be used to stop a bolt falling out of the application during assembly. They slide down the thread and hold firmly at any point so when the panel or component is installed they stay in place. The teeth fold flat so they add very little extra thickness to the final assembly.

Road safety

There are any number of safety risks associated with cables and hoses in vehicles. Hoses carry flammable fuel, brake fluid or hydraulic fluid - all essential for safety in vehicles. Even a damaged windscreen washer hose can make you less safe behind the wheel. Problems result from vibration that can dislodge cables and hoses or cause chaffing. Cable or pipe clips with flared edges reduce the chance of damage when cables or hoses rub against them.

Vehicles in the future

The good news about EVs (Electric Vehicles) is that they don’t vibrate as much as fossil fuel vehicles. But voltages in EVs will leap from 12V AC to 440V DC or higher. These potentially lethal voltages also generate considerable heat. And LiDAR (light detection and ranging) systems in AV’s (autonomous vehicles) will involve a lot of cabling.

Any manufacturing fault is a potential safety issue, that’s why quality control is so important. If you use different colours for similar parts it’s easier to spot the wrong one and this applies if the inspection is done by humans or robots. Designers use coloured parts from yellow zinc plated T-nuts in furniture to coloured hose bands in vehicles.

“JET PRESS stocks a huge range of cable and hose clips and has a great deal of experience solving design issues in cable and hose management in vehicles. Our team is always happy to discuss the options available to you and work with you to find the best possible solution.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.