NOF METAL COATINGS GROUP has been a leading coating supplier for more than 40 years and is continuously developing new products and meeting new requirements. The commercial and technical success of its PLUS® VLh topcoat – in combination with the GEOMET® basecoat – helps create a system of high corrosion performance and perfect friction control.

Mastering the science of friction behaviour

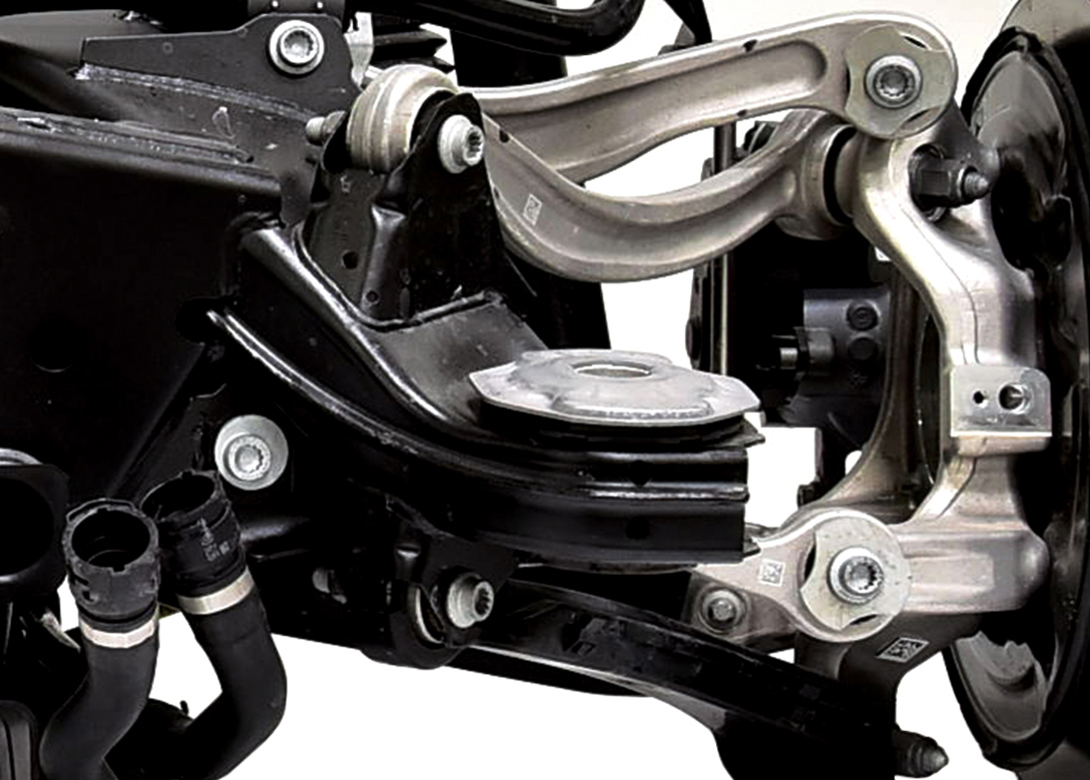

The primary function of a threaded fastener is to ensure a specified clamp load. To that extent, fastener coatings are designed to not only give corrosion protection but also to bring the right assembly characteristics, ensuring that the applied torque brings the needed clamping force and a secured safe joint. These demands are assessed by testing friction in a controlled environment.

The specifications define parameters to verify characteristics such as torque or clamping force. Multi-tightening testing can be part of these test specifications, especially for wheel screws testing where it’s an important feature.

To ensure the needed clamping force will always be reached, the test specifications define the range of a friction window that on one hand guarantees a minimum clamp load and on the other hand avoids overloading the screw. Most of the OEMs request this against several types of material like e-coat, aluminium and steel, all for the same screw with one coating system only. Top coats developed by NOF METAL COATINGS GROUP successfully reach all these requirements.

Many fasteners have been used with phosphate and oil for a very long time and electroplated fasteners can answer torque/tension requirements. However, since zinc is the major metal used for corrosion protection, only zinc flake coatings such as GEOMET® systems are able to provide at the same time a very good and adjustable coefficient of friction (COF) together with the highest corrosion protection.

Years of reaching new requirements on friction coefficient behaviour

NOF METAL COATINGS GROUP is the manufacturer of GEOMET and the inventor of zinc flake coating systems. The GEOMET system for corrosion protection and friction control made NOF METAL COATINGS GROUP the leader of zinc flake coatings in the market. With its PLUS® portfolio of topcoats, the Group has been able to always reach new OEM/tier 1 customers and continuously serve the market over the years.

Key milestones in the market include:

- In 2000, the friction test focused only on one tightening against steel at low speed (<30rpm) described by general automotive specifications such as VW TL 245 and DIN 946, or DBL 9410 [µ = 0.08 – 0.14].

- In 2005, e-coat was introduced as a bearing surface for friction testing. A new focus on stick slip (high speed pre-assemble speed at e.g 200rpm) and also loosening torque at 150°C were introduced.

- In 2013 there was an improved focus on aluminium as a bearing surface and also the assembly of steel coated screws in aluminum threaded parts. Multi-tightening (e.g 5 times) was also requested in the OEM specifications. This was the impulse for NOF METAL COATINGS GROUP to develop its new PLUS® VLh, based on the very successful PLUS® VL, which had proven its stability and cost reduction potential in the assembly chain.

Through these milestones NOF METAL COATINGS GROUP confirmed its role as the leading coating supplier, in close contact with the market, and its ability to introduce a product that fulfils new demands of OEM and tier 1 customers.

The new PLUS VLh topcoat has been successfully used for series production in the truck and automotive industries, as well as in other markets such as wind energy. The coating technology has also proved once again that NOF METAL COATINGS GROUP is able to fulfil the increasing requirements from reputable OEMs, such as VW-AUDI (VW 01131) and DAIMLER (MBN 10544).

PLUS® VLh – perfect friction control

The development of PLUS VLh was based on the improvement of the already performing characteristics of the PLUS VL – in combination with the GEOMET basecoat – to create a system of high anticorrosion performances with excellent assembly characteristics.

GEOMET is a chromium-free waterborne anticorrosive coating that can be applied as a thin sacrificial coating layer. This basecoat can be applied as bulk during a dip-spin operation but also on rack or by spray for bigger parts applications. PLUS VLh topcoat is also waterborne and can be applied using the same coating process.

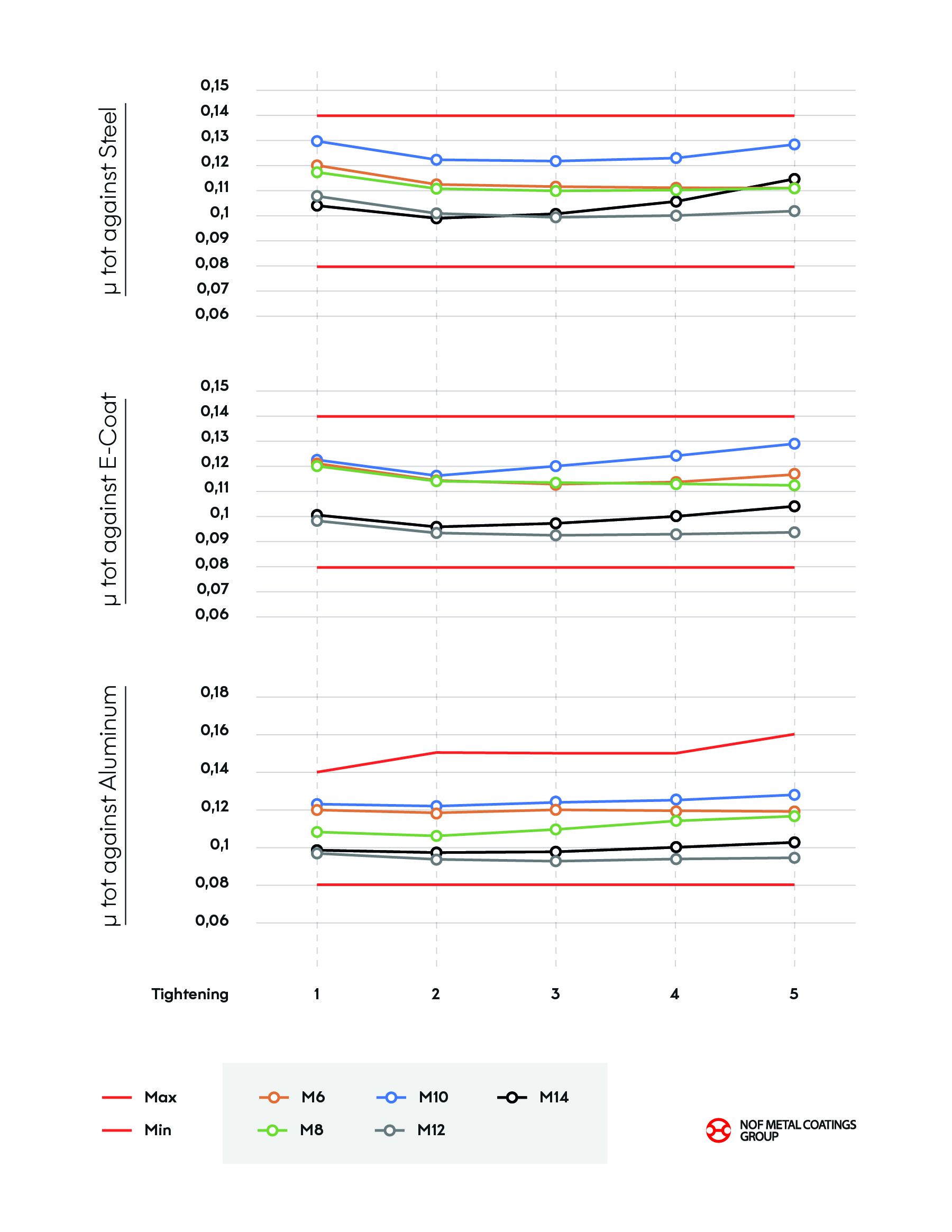

The development of PLUS VLh integrated the demand for stable friction coefficient on different bearing surfaces (steel, aluminium, e-coat) but also anticipated the request regarding high speed tightening (till 700rpm for M6). The PLUS VLh chemical contains binders, lubricants and waxes. Each raw material was selected and adjusted considering its influence on friction properties of the film.

The combination of GEOMET and PLUS VLh not only provides corrosion performance and controlled friction properties, but also improves abrasion resistance and thermal resistance to the coated part’s surface. PLUS VLh also exhibits very reliable performances whatever the bolt geometry. A statistical analysis on different diameters demonstrates the good COF stability, which stays in the same range for all bolts’ sizes.

In the charts pictured there are examples of the different values.

PLUS® VLh high-level standard

The combination of GEOMET and PLUS VLh top coat is a very robust coating system – helping to solve almost all kinds of assembly issues that could generate high costs in the assembly line versus the individual low cost of a single fastener.

The successful introduction and the commercial success of PLUS VLh confirm the very high skill level of the NOF METAL COATINGS GROUP’s teams and its GEOMET licensee applicators in the field of anticorrosion and lubricated coatings for fasteners.

NOF METAL COATINGS GROUP produces and sells GEOMET and PLUS VLh all over the world. More than 580,000 tonnes of screws have been coated with PLUS VLh since 2013. Its high-level of performance enables it to be specified for other types of industries such as wind energy or trucks, on parts such as U-bolts and wheel bolts, where safety must be guaranteed. In addition to standard grey/silver, the system with PLUS VLh is also available in black colour.

NOF METAL COATINGS GROUP continues to work on the operational excellence of its solutions – whether it be from a product or application process point of view – to further establish its technical robustness and commercial success.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.