Lightweighting is at the heart of the current challenges of the automotive industry, with electrified vehicles needing to reduce their weight. To meet this goal many solutions now replace metal components with plastic. However, for certain applications, which require clamping forces to remain fixed, the effects of creeping needs to be avoided.

Indeed, during a traditional assembly of plastic components with screw and nut, plastic deformation appears over time, thus causing a drop in tension of the assembly and the risk of loosening of the nut and the bolt. This can lead to costly, time-consuming and, in the worst-case scenario, dangerous situations. What if more than one screw loosens in a car within a single assembly system?

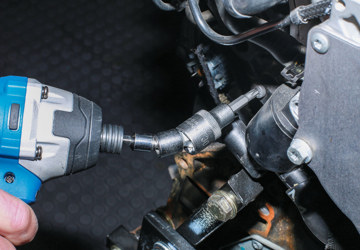

The function is to reinforce clearance holes in plastics to provide a metal to metal contact allowing the application of clamping forces and limit the compression to avoid over-stressing of the plastic. LISI Automotive’s multidisciplinary teams have developed a complete range of anti-creep solutions including anti-creep rings - elastic and non-elastic, round, oval, square, etc, as well as anti-creep shoulder screwsm- in steel 10.9, steel 8.8, aluminium and EGH, etc.

In addition to allowing a durable and safe assembly, LISI says its anti-creep solutions have advantageous characteristics including different panel thicknesses possible, stability of the preload under flexible assembly, as well as speed of assembly thanks to the pre-assembly position for the shoulder screws. The solutions have also been tested and validated, such as corrosion, environment etc, and there are also existing solutions in M6 – for anti-creep rings – and M8 and M10 for shoulder screws.

“Our ability to advise on the most suitable solution for each need allows us to support our customers, mastering all technical and economic aspects. For example, the total cost of the assembly function differs depending on the amount of parts used per year, including the cost of the anti-creep solution, the cost of assembly at the plastics manufacturer and the cost of the final screwing,” explains LISI Automotive.

LISI’s multidisciplinary experience in threaded fasteners and in clipped assembly solutions allows the company to offer complete solutions incuding anti-creep screws, anti-creep rings, standard assembly screws and nuts, etc, which can be adapted to specific applications.

“For any other request, do not hesitate to contact us and we will be happy to help you find or design the solution that best meets your needs.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.