By working closely with everyone involved in a project – from engineers to suppliers and OEMs – omniTECHNIK provides optimal solutions for locking and sealing, as well as controlled assembly and disassembly, thanks to its precote® range of high-tech products.

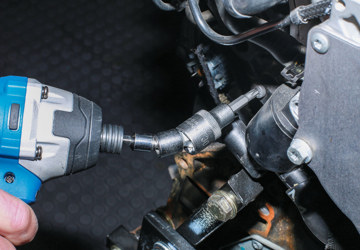

Precote® products are specially designed for the pre-coating of threads and are based on a unique microencapsulation technology, which enables omniTECHNIK to offer many advantages over conventional thread lockers. “It is only during assembly that the precote system gets activated, cures and provides reliable locking and sealing of the thread,” mentions omniTECHNIK Mikroverkapselungs GmbH. “This makes precote the ideal solution for all application areas – where high standards in operational safety, easy handling, and efficiency in mass production, are required.”

omniTECHNIK points out the success of precote is thanks to the company’s global presence and the long-term relationships it has created with customers.

“Germany has always been very strong in terms of engineering and this certainly applies to omniTECHNIK and precote,” states the company proudly. “We have spent a lot of time and invested a lot into our technical service, as it is key to our development. We created strong partnerships with our coating partners around the world and together we develop solutions for new applications in a close teamwork.”

The company adds: “We do not only deal with the coating partners, but also with everyone involved in a project – especially the engineers at the supplier and OEMs. Providing the best quality service is vital, so it is important to involve everyone from the beginning. If somebody fails, the whole design fails and everyone must be aware of what to pay attention to. Innovation is a matter of mindset – we have a top class technical service team, which is absolutely crucial in our success.”

As well as this, omniTECHNIK still looks to keep innovating internally. “It’s important we’re constantly looking at our current portfolio of products to improve them, as well as looking at creating new products. This involves looking at new fields and new markets and staying ‘one step ahead’ – facing these challenges head on and innovating.”

“The future for omniTECHNIK will see us continue to work together with our partners. We don’t see a big change because the basic requirement for threadlocking and sealing products will not change dramatically. However, we’ve seen German companies take a positive approach to the shift to eMobility and we can identify a need to have more specialised products for smaller screws. Finally, sustainability is an important topic for us, so we will continue to focus on improving our manufacturing in existing processes, as well as newly planned processes. We are proud that ‘Made in Germany’ is still a quality label that our customers can rely on and trust and we are also proud that omniTECHNIK is a market leader in the field of threadlocking and sealing products, as well as coatings for fasteners.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.