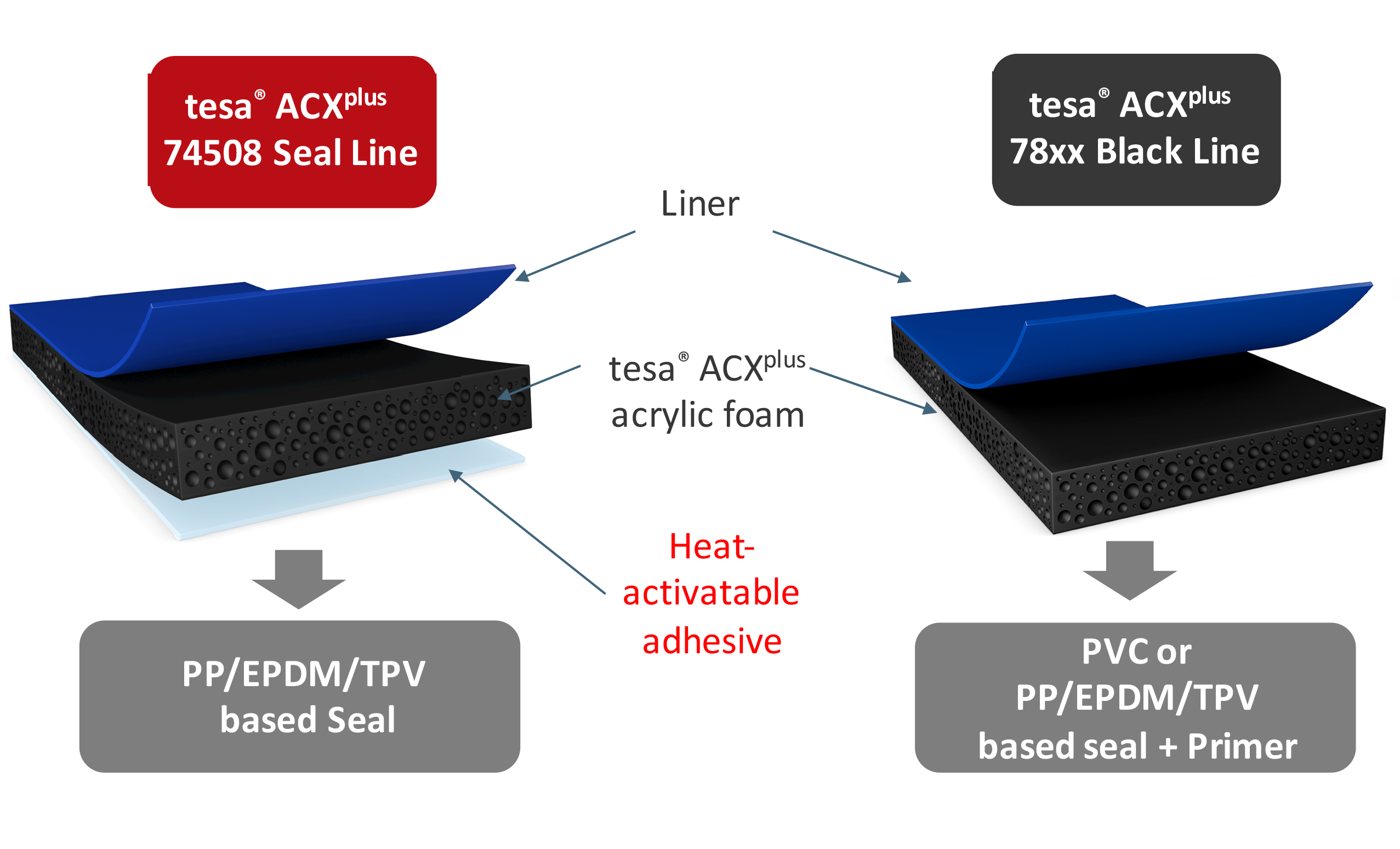

Already established across industry with ‘viscoelasticity’, a unique bonding technology that compensates for the differing thermal expansion rates of dissimilar materials delivering excellent stress dissipation, tesa® has now introduced ACXplus 74508 Seal Line and ACXplus Black Line to the automotive market.

Developed for use with polypropylene, TPV (thermoplastic vulcanisate) seals and PVC, the tapes can be used in a variety of applications in the automotive sector including the mounting of window seals, water box seals, sunroof seals and obstacle detection systems. The dense black finish from tesa® ACXplus Black Line adds a further design element and an enhanced appearance that will appeal to car owners.

The products are both based on a viscoelastic acrylic foam core and Seal Line offers an additional heat-activated adhesive layer to the sealing side.

Tier 1 and automotive suppliers, which provide a range of technical gaskets for under-bonnet, glass and roof applications, are using the new tesa ACXplus products for reasons of functionality and performance. In doing so they are often able to replace metal carriers with recyclable plastics and contribute to both weight and cost reduction programs. tesa ACXplus tapes are laminated, for example to an EPDM profile by a converter, and provided to OEMs who will simply remove the liner on the tesa ACXplus adhesive side and apply it to the glass.

The advantages of using heat-activated tape for PP/EPDM/TPU based window seals and water box seals include secure bonding and a more efficient application process. The process is also more environmentally friendly as no primer is necessary

In addition, the tesa ACXplus range employs the unique PV28 liner, a silicone-free HDPE-filmic liner which removes any liner-lift problems.

tesa explains that OEMs have been quick to recognise the benefits of the new range with test passes achieved on tesa ACXplus Black Line. Manufacturing tests have produced some outstanding results with peel, tensile shear and creep tensile shear results showing the products outperforming standards requirements from 3 times up to 339 times.

In summary, tesa says its ACXplus 74508 Seal Line will offer automotive glass and car manufacturers a range of performance and aesthetic benefits. Better bonding will result from the heat-activated layer to the backing, water box seals will have higher stiffness and the PV28 liner will obviate any lifting up problems. tesa ACXplus 78XX Black Line delivers superior bonding power and best cold shock performance, along with its deep black colour for design flexibility.

The advantage of adhesive tape technology to the automotive sector is now well established. Not only does its use contribute towards design standards, weight reduction and emissions control, it’s also light, clean and easy to use whilst being durable, safe and environmentally friendly.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.